Case Study:

Efficiency Improvement via Lean Line Reconfiguration

Industry

Personal Protective Equipment

Budget

<£10k

Task

Solution

Standardised Jigs and Reconfigured line

Productivity increases without the price tag

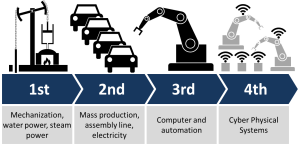

This project was delivered by our industrial automation team as part of our ongoing work helping manufacturers modernise their production environments. The customer for this project is a world-class manufacturer of personal protective footwear looking for ways to increase efficiency and lower costs. They have an automated post-processing machine which requires two operators to run. They were interested in moving one of the workers to another higher-value area and had seen some of the incredible things robots were able to do. So, they asked us to come and have a look and scope out a solution where they could implement some automation and bring down the headcount on this process.

The Challenge

The customer’s setup of their semi-automated cell needed two operators. They wanted to reduce the headcount in this area and possibly automate the loading and unloading of components.

The area had non-standard jigs and a variety of products using the line. Accommodating the existing jigs and all product variants would have required a significant investment to ensure robust and reliable operation.

We looked at the prerequisites for automation and took a holistic review of the process. It appeared that there was an opportunity to reach their goals in other ways. This required a blend of automation engineering insight and lean line analysis to ensure the redesign aligned with the client’s operational goals.

Our Approach

Our team applied industrial automation methodologies to map out the workflow, ensuring that any layout changes supported more efficient movement, safer operations and repeatable automated processes.

- On-site consultation: We process mapped the current cell’s flow and throughput, timing each portion and calculating the Process Cycle Efficiency (PCE) https://omnatec.com/knowledge-base/lean-part-1

- Ejection concept design: : We created concepts for a standard jig and tested ways the finished goods could be ejected automatically

- Rapid prototype and test: We created some prototypes of the jigs to automatically unload the parts and tested them on and off site.

- In-house rollout: With the results of the testing, it was clear that a solution was feasible. We created a plan and the customer tasked an engineer to create the next prototypes and test them out.

The Results

With the jigs now standardised and able to automatically eject the components, the customer was able to reconfigure their cell.

- Labour redeployment: One operator was freed for other higher-value tasks, halving the labour cost on the parts and boosting the overall factory capacity.

- Zero capex on robotics: All hardware costs were under £1,000 and the Omnatec consulting cost were under £6000, delivering an ROI under two months. https://omnatec.com/knowledge-base/three-biggest-mistakes-when-trying-to-boost-manufacturing-

- Flexible Resourcing: The customer could choose to use Omnatec resources or their in-house resources to be most cost-effective and efficient for the project. We want to be an extension of your team and work together towards your goals, whichever way works best for you.

- Scalable solution: The reconfiguration kept the door open for further improvement in the future, with possible capacity increases coming from either automation or traditional optimisation projects.

Looking to the Future

Working onsite with the customer, we found that the cell could run without a second operator by redesigning the unload process and reconfiguring the line.

The lean ejection solution delivered a rapid, low-cost win by maintaining the cell’s throughput, moving a worker to another higher value task and all without any significant investment. OmnaTec’s holistic, process-driven approach, commitment to customer satisfaction and flexible approach to project execution all helped the customer achieve their goals with almost an immediate ROI.

By rethinking rather than replacing, the customer was able to unlock immediate capacity gains and laid the groundwork for future further improvement and automation. The project highlights how a trusted industrial automation company can drive measurable gains through targeted reconfiguration and lean restructuring.