Why Semi-Automation is the Smart Move and How to Get Started

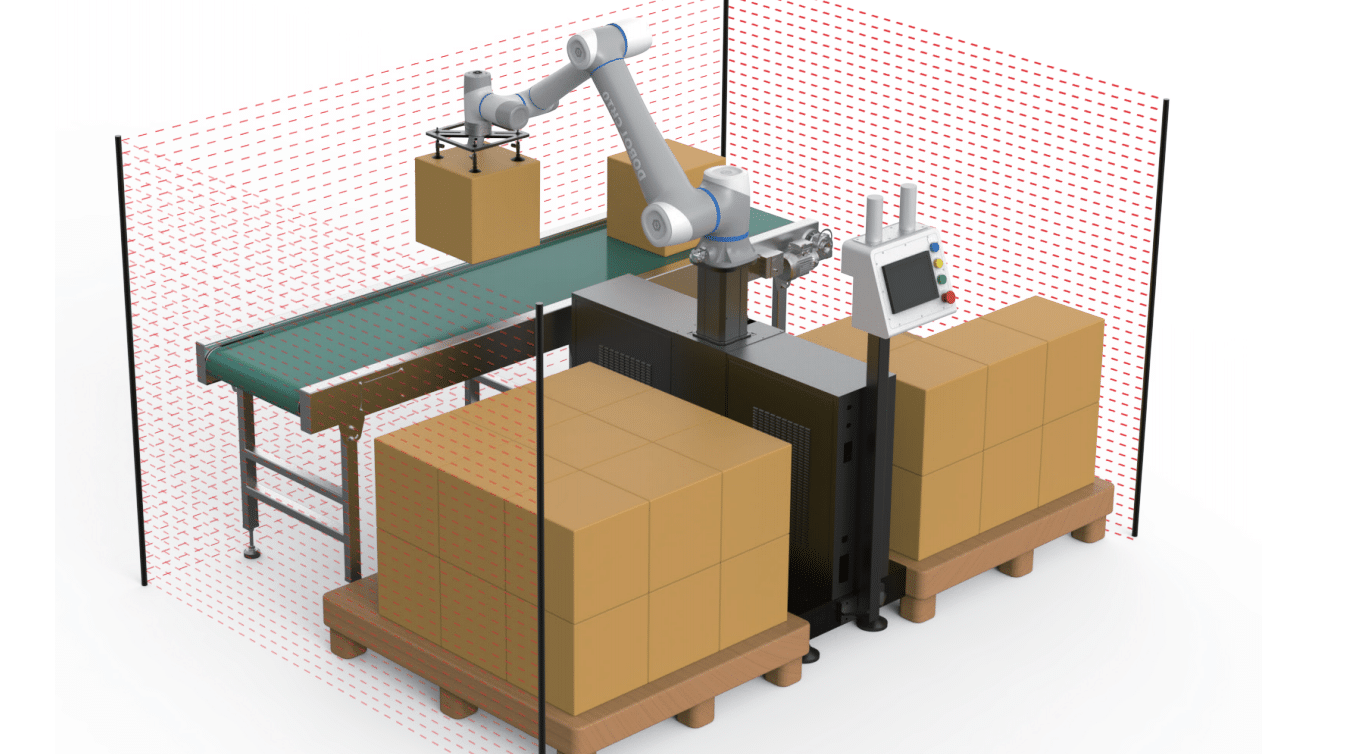

SME manufacturers are always looking for effective ways to increase productivity and reduce costs in a high mix/low volume environment, which often means looking to some form of factory automation. Semi-automation offers a practical approach that combines human oversight with automated processes, ensuring that critical tasks are completed efficiently while still benefiting from the nuanced decision-making of a skilled workforce. It can be especially impactful in areas like:

- Warehousing (https://www.sdcexec.com/software-technology/automation/article/22171793/westfalia-technologies-inc-manual-vs-automation-a-battle-with-two-winners)

- Batch assembly (https://www.assemblymag.com/articles/97869-manual-semiautomatic-or-fully-automatic)

- Welding (https://bancrofteng.com/semi-automatic-welding-machine-best-choice/)

For SMEs wanting to benefit from factory automation, semi-automation serves as a pragmatic middle ground, allowing businesses to streamline operations, mitigate risks, and scale gradually while maintaining the essential human oversight required for nuanced decision-making, which is expensive to automate.

Understanding Semi-Automation

Semi-automation refers to automating some steps or tasks in a workflow while maintaining human involvement for oversight and decision-making. Unlike full, or fixed, automation, which aims to eliminate human intervention entirely, semi-automation strikes a balance by automating repetitive, dangerous, or labour-intensive processes while allowing workers to manage exceptions, ensure quality, and adapt to variability. This approach provides SMEs with greater flexibility, as it requires lower upfront investment, is easier to implement, and can be gradually scaled as business needs evolve. By keeping humans in the loop, semi-automation reduces the risks associated with making the jump all the way to full automation.

Benefits of Semi-Automation for SMEs

Cost-Effectiveness

Semi-automation enables manufacturing SMEs to invest incrementally, reducing upfront costs typically associated with full-scale automation projects. It also acts as a labour multiplier by enhancing the productivity of skilled workers rather than replacing them entirely.

Example: A manufacturing plant might begin by automating their repetitive screw fastening tasks, while retraining their workers for quality inspections. This approach could minimise labour costs, but more importantly, it boosts the overall output of each employee as they can focus on more value-added tasks.

Speed of Implementation

Deploying semi-automated solutions tends to be faster, enabling businesses to see improvements without lengthy installation and integration processes.

Example: A small manufacturing business can quickly deploy an automated inventory tracking system alongside manual stock counts, ensuring immediate improvements without halting operations.

Enhanced Flexibility

By combining automation with human oversight, semi-automation offers a flexible approach that adapts to varying circumstances and handles exceptions effectively.

Example: In a welding shop, automated welding equipment can perform standard welds while experienced operators handle more complex joints that require manual precision.

Risk Mitigation

Transitioning directly from a fully manual process to full automation can introduce significant risks, such as , technical issues, or reduced flexibility to changing market and production needs. Semi-automation helps mitigate these risks by giving SME manufacturers stepping stones to get benefits and find balance.

Moving directly from a manual assembly process to a fully automated system can have risks to production, like unknowns in the process and inconsistent part tolerances, all while reducing their flexibility to changing market and production needs. Semi-automated assembly help bridge this gap by maintaining human involvement where flexibility or problem-solving is required. This reduces the risk of costly downtime and allows businesses to fine-tune automation before committing to full-scale implementation.

Example: A manufacturer assembling small mechanical components introduces a semi-automated fixture that holds parts in place and uses pneumatic actuators to assist in fastening. While the fixture automates positioning and reduces operator fatigue, workers still handle final quality checks of both base components and final assemblies. This setup minimises assembly errors while allowing operators to adjust for slight variations,

Scalability

When used as part of an automation strategy, this approach provides a scalable platform that can grow with the business, allowing gradual expansion of automated processes as needs evolve.

Example: A stock control system in a manufacturing facility might start with automated tracking of raw materials, and as production grows, further integrate automated reordering and inventory management systems across the entire supply chain.

Steps to Implement Semi-Automation

Successfully implementing any automation project whether fully or semi-automated should be done as part of a strategic approach. Each project within this strategy should have a structured approach with clear objectives a phased plan for achieving them.

Strategic Planning

- Set Clear Company Automation Goals: Define what you aim to achieve (e.g., reduced errors, faster processing times).

- Create a roadmap: An Automation Roadmap will lay the groundworkfor how you are going to achieve your goals.

- Stakeholder Engagement: Involve key team members from the start.

Find the Right Partner

Find an Automation or Integration partner who can help you navigate the automation options and who understands your needs.

- Industry knowledge: An automation partner will bring a fresh set of eyes to your factory and processes. They will have the experience to guide you on where to start and where you could end up.

- Your Business: An automation partner should be looking at your factory holistically and not be solely focused on the small part they may be working on at the moment. With Omnatec your success is our success.

Project Steps

Define your Project Scope

- Identify a task or process: In the next section, “Identifying the Best Opportunities for Semi-Automation” we will look at this in detail

- Look holistically: Analyse the effects on your overall throughput based on the project’s goals

Concept Design

- Develop initial automation concepts: Outline possible semi-automation solutions, considering factors like ease of integration, cost, and expected benefits.

- Evaluate feasibility: Assess space requirements, compatibility with existing processes, and fit into the automation strategy.

Solution Development

- Select and procure equipment: Choose hardware and software that align with the project scope and business needs.

- Build and integrate: Build and test the solution, testing high-risk sections earlier to mitigate the risk. Ensure project goals will be met.

Final Testing and Commissioning

- Conduct Factory Acceptance Test (FAT): Test the system in real production conditions to ensure the required metrics are met.

- Optimise performance: Fine-tune automation settings based on test results and operator feedback before full deployment.

Handover and Training

- Train operators and staff: Ensure engineers and technicians understand how to use, maintain, and troubleshoot the new system.

- Establish support processes: Review the maintenance schedules and hand over the documentation and manuals.

Identifying the Best Opportunities for Semi-Automation

Before implementing semi-automation, it’s important to identify the processes where it will have the greatest impact. By analysing workflows, assessing feasibility, and testing small-scale solutions, SMEs can ensure they target the right areas for automation while maintaining efficiency and flexibility. Make sure that whatever is identified fits in your Automation Strategy and you have a plan for future scenarios.

Process Mapping and Analysis

- Current Workflows: Document existing processes and workflows.

- Bottleneck Identification: Identify repetitive tasks and common pain points. (https://omnatec.com/knowledge-base/toc-whats-your-bottleneck)

- Employee Input: Involve team members to gain insights on manual inefficiencies.

Assessing Impact and Feasibility

- ROI Evaluation: Analyse capacity increase gains and productivity improvements.

- Process Frequency and Volume: Prioritise tasks that occur frequently or involve higher volumes.

- Complexity Assessment: A good rule of thumb for semi-automation is to use the right solution for the right type of task:

- Human labour: flexiblity, evaluation, non-conformities

- Automation: precision, speed, high risk

Pilot Testing

- Small-Scale Trials: Implement a pilot project to validate the automation concept.

- Feedback Loops: Collect data and employee feedback to fine-tune the approach before wider rollout.

Start your Industrial Automation Journey

Semi-automation offers a practical, cost-effective solution for SMEs looking to enhance productivity without full factory automation’s risks and high costs. By carefully evaluating your processes and piloting targeted automation projects, you can achieve significant efficiency gains while retaining the flexibility that has made many SMEs so successful. Semi-automation not only meets immediate operational needs but also lays the groundwork for future automation initiatives.

As a next step on your automation journey, you can learn more about our industrial automation solutions or drop us a line.