Palletising Products:

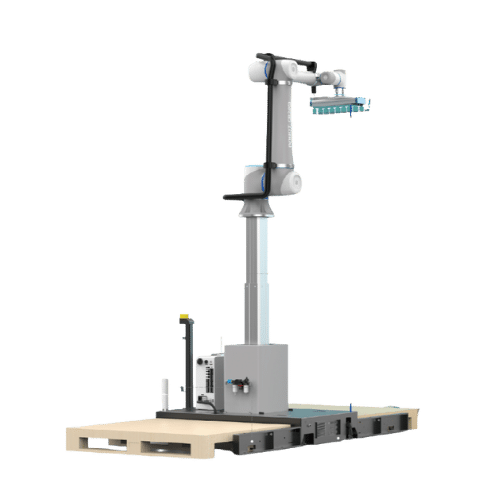

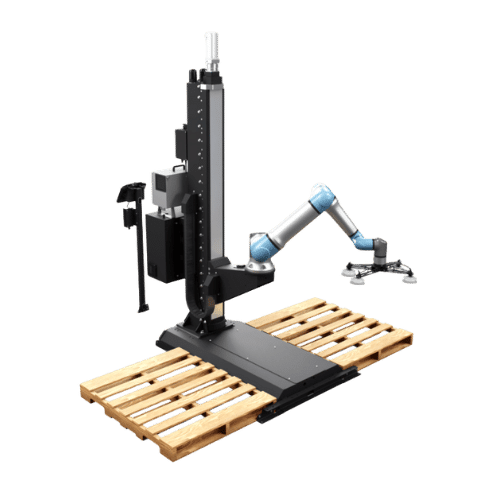

Cobot Palletiser

Introducing the OmnaTec Automated Palletiser Range

Flexible

Our automated palletiser range accommodates the variety of boxes you may have, as they can easily be moved between conveyors to palletise different lines. They can also accommodate multiple box variations and box pattern arrangements. The programming is intuitive, so following our initial training, your operations staff can easily update and recreate box patterns if boxes change or new products are brought online, unlike traditional palletising robots that require specialist engineers.

A Size to Suit All SMEs

Our range of automated palletisers covers the majority of payloads required by our customers (11.5-27 kilos), and the small footprint of the cobots means that the large open spaces required by an industrial palletising robot system are no longer needed, allowing you to maximise your facility footprint. As a part of our service, we will identify the right model and configuration for your manufacturing needs.

Worker-Safe

Peter Shafe, Co-founder & Director

Solutions for Your Manufacturing Challenges

-

Exceptionally Small Footprint

Compact enough to ensures your palletisers can be integrated with the existing equipment and systems.

-

Easily Reprogrammable

Our automated, flexible palletising cobots can be easily reprogrammed by your existing personnel to suit different configurations and payloads.

-

Proven Safety Features

Relevant safety protocols can be configured to meet your plant's safety requirements so your factory floor workers can work safely side-by-side with our cobots.

-

Fast and Strong

Day in and day out, our palletisers will ensure your end-of-line processes keep up with all production demands.

-

Flexible Redeployment

Our cobots offer the flexibility that traditional palletising robots can’t. They can be relocated quickly between lines or adjusted to match changing production runs.

-

Frees Up Employees

Addresses issues with recruitment challenges preventing growth and frees up skilled employees to work on other areas.

-

Boost Productivity

With consistent and reliable output and no manual errors your production levels will soar, helping your bottom line with lower costs and providing an excellent ROI.

Choose The Right Palletising Cobot System for Your Factory

Choosing the right palletiser system for your factory requires us to evaluate your box sizes and weights, end-of-line throughput, and pallet size.

Palletiser Model:

Size:

Max Payload*:

Max Palletising Pace*:

Max Palletising Height*:

Lift:

Palletiser Specifications

*1. Max Payload: Does not include the weight of the end-effector vacuum gripper

*2. Max Palletising Pace: The actual palletising speed depends on the weight, size, and layout of boxes

*3. Max Palletising Height: The size and layout of boxes may affect the actual palletizing height

Automated Cobot Palletiser FAQs

Below are frequently asked questions, and if you have any of your own, please get in touch.:

Understanding Cobot Palletisers

What exactly is a cobot palletiser and what tasks can it automate?

A cobot automated palletizer is a collaborative-robot system for the end of production lines that stacks a range of product types (boxes, bags, trays, punnets) onto one or more pallets at an end-of-line station. It combines a four or six-axis robot arm with end-of-arm grippers (vacuum, mechanical fingers) and software to handle varied payloads and patterns. This automatic palletising removes the heavy, repetitive lifting so you have fewer HSE incidents and your staff can focus on quality checks, change-overs and higher-value duties and this reduction in manual labour makes it highly cost effective.

How does a cobot differ from a traditional industrial robot palletiser?

Industrial systems prioritise speed and payload to meet the needs of high volume manufacturers, so they require large fenced-off zones and expensive guarding. Cobot palletisers run at slower speeds, with lighter payloads (commonly 10–25 kg per pick) and have force-torque sensors with advanced safety protocols to slow or halt on contact with a human operator, eliminating bulky fencing. This allows them to share the space with people with minimal guarding and in a footprint up to 70 % smaller than their Industrial counterparts.

They often also feature easy-to-use graphical programming interfaces to allow box patterns to be added and/or updated by the users. Industrial palletising robots have historically required a robot programmer, but many newer robot palletisers are also adding an easy to use programming functionality into their products.

See our article on why a cobot palletiser might be a good fit for you.

What range of box sizes, weights and layer patterns can your cobots handle?

Anything that fits within the model’s envelope, but keep in mind there is a trade-off between size, weight and speed while maintaining the collaborative aspects of the cobot palletiser. Cobot palletisers work best with box sizes less than 16kg; however, they can go up to 25kg. The pallet heights can be up to 2.75 m with a linear lift for the cobot. However, it is best to keep it under 2m if possible. Layer patterns are built in drag-and-drop software, so mixed-layer, irregular, or display pallets are all possible.

What is the difference between a robot and a cobot?

A cobot (collaborative robot) is designed to be able to safely share workspace with factory-floor workers. The latest update to ISO 10218 standard, which covers the use of robots including cobots, clarifies the safety measures needed for human-robot interaction in a robot application. There are really no collaborative robots out of the box, but collaborative applications that, when designed correctly, can make use of the integrated force and torque sensors in a cobot. These applications run slower and have less force than a traditional robot application which would require a fenced zone. While the guarding can be cumbersome and difficult to fit in many tight SME factories, it allows a traditional industrial robot to achieve much higher speeds and payloads. Cobots also tend to have much more user-friendly programming interfaces and custom software addons to make the palletising set-up fast and easy. You can learn more here in our article.

How much weight can a cobot lift?

Most collaborative arms can lift up to 25 kg (including the gripper). This usually means that each lift shouldn’t be more than 18kg. There are some options on the market, such as those in our Ultimate Palletiser line, which can lift 30k,g including the gripper. If your product is heavier than this, we can help you install an industrial robot palletiser.

Palletiser Deployment & Integration

How much factory floor space does a typical cobot palletising cell occupy?

It depends on the model and number of pallets being filled, but most are approximately 2.75 m x 1.75m. This is typically one-third the footprint of an equivalent industrial palletiser.

Do automated palletizers need safety fencing or other guarding to operate?

Often no. Under ISO 10218-1 collaborative mode, cobots use torque-based collision detection to operate without physical barriers, monitoring forces across six axes to stop instantly on contact. Integrators may fit light-curtains or area scanners to allow higher speeds; if a person enters the zone, the cobot slows to safe collaborative speed until the area clears. In all cases a risk assessment is conducted and often it is acceptable to run with light curtains or laser scanners only. Hard guarding is added only if extra hazards (sharp case edges, high-speed conveyors) are present, but many space-efficient applications omit it altogether.

Can a cobot work safely alongside human operators without disrupting workflow?

Yes. Built-in torque sensors and safety firmware let cobot arms detect collisions and stop in milliseconds, making them compliant with collaborative-robot safety standards. Many cells also integrate 3D vision or light-curtains, so the arm pauses when staff enter the zone and resumes automatically when clear. The slim cell layout leaves clear aisles so operators can replenish separators, remove full pallets or load products without halting the entire line.

Can the palletising cobot be moved easily between different packing lines?

How simple is it for production staff to create or change pallet layer patterns?

Unlike most palletising robots which require specialist engineers to make changes, for most palletising cobot models it is very simple. This is because they feature intuitive, graphical “drag-and-drop” or block-based programming GUIs that let operators draw layer patterns in minutes, without code. You just have to choose the box size, drag boxes into rows in the software. Some models also offer simulations to allow users to preview and tweak stack sequences. Most operators master it in a single training session.

Will the cobot integrate with my existing conveyors and end-of-line equipment?

The answer is: Maybe.

If we can use your existing equipment, we will. However, often even if there is an existing automatic conveyor, we will add a small length of conveyor to ensure the box placement and sensor installation provide a reliable box pick-up position.

Economics & Selection Strategy

What return on investment (ROI) can a small-to-medium manufacturer expect?

Typical payback is 12–24 months through labour savings, fewer manual-handling injuries and more consistent pallet quality, but if an application is in the “sweet spot” of a cobot operational envelope in terms of throughput, pick rate and payload, it could be less than a year.

How much does a cobot palletiser solution cost?

A typical cobot palletiser solution for an SME starts around £55,000–£65,000 and could go up to as much as £120,000 depending on the model, end-of-arm tooling, guarding, and any conveyor integration. For a straightforward pick-and-place application with the stacking a single variety of uniform boxes, the lower-cost options will work. If you require dual pallet positions, multi-size handling, or extended reach, the budget will need to be closer to the high end. At OmnaTec, we always work to align scope with your ROI target, and most of our projects aim for payback within 24 months, but depending on your expected usage rate and labour rate, payback could be under 12 months.

What is the life of a cobot?

Whilst this will vary depending on a number of variables, many manufacturers quote around of 35,000–50,000 hours of run time or 8–12 years of service in most SME environments, assuming proper servicing schedules are adhered to and the robot is not running at maximum speed and torques. Most models come with standard warranties of 1–2 years, with extended support available. The key to a long life is sizing the cobot appropriately for your application, which means keeping payloads and cycle times within the robot’s comfort zone.

Are palletising cobots cheaper than robot equivalents?

Which cobot is best?

This can only be answered by looking at your exact needs, both currently and in your future automation strategy. When engaging with OmnaTec, we will always ask a range of questions, including the specifications of the current product range, the likelihood of future products outside the existing envelope, the in-house support resources and the budget allocated. We will try to find you the best solution to meet your needs.

When would a business use a palletising cobot instead of a traditional palletising robot?

If you have any of the following challenges in your factory, then you would benefit from a cobot palletiser over a traditional robot.

- Tight floor space

- You plan to relocate or alter your floor space

- You have frequent SKU change-overs or changes to production output

- Need to redeploy the robot between lines

- When you only need a moderate throughput

- You need personnel access to the working area

How do I choose which cobot?

OmnaTec provides full consultancy as part of the service, ensuring that you end up with the right result. Key amongst our considerations to ensure that you get the right cobot palletiser for your needs is knowing your max payload, reach and pallet height. Other considerations are what your cycle-time target is and what safety guards and protocols are needed or present. All of our cobot palletisers are easily reprogrammable, and we will provide support for peace of mind. With all these factors established, we can demonstrate the ROI you will achieve by selecting us as your cobot palletiser partner.

How do box size and weight affect the real-world palletising speed?

Box size and weight are two of the biggest drivers of real‐world palletising speed. Heavier boxes force robotic arms to slow acceleration and deceleration for safe handling, weight checks can introduce extra pick‐and‐place steps. Larger or irregularly shaped boxes often require longer travel paths, reduced approach speeds at corners, and more complex box presentation for gripping, which all increase cycle time. If the palletiser is over spec’d, there will be extra capacity in the robot, but if boxes are too big or too heavy, and the robot spends extra time gripping, moving and positioning it can have a significant effect on your operation.

- How Box Weight Affects Palletising Speed

- Reduced Acceleration/Deceleration

Robots automatically limit acceleration when handling near‐payload loads to keep joint torques within safe thresholds. - Weighing Overhead

Force‐sensor or scale checks (to validate carton fill levels) insert additional pause cycles (typically 0.3–5 s per box)before placement. - Grip Dynamics

Heavier packages require slower gripper actuation (vacuum chambers need longer to build suction under load), reducing picks/min by 5–15% compared to light boxes.

- Reduced Acceleration/Deceleration

- How Box Size Affects Palletising Speed

- Longer Reach Paths

Larger cartons increase the robot’s travel distance to cover full layer footprints; each extra 100 mm of reach can add 20–50 ms per pick cycle. - Complex Pattern Planning

Irregular or oversized boxes often require bespoke path trajectories and slower approach speeds to avoid collisions, potentially adding 0.2 s per placement. - Reduced Bulk Picks

A gripper can pick entire rows or layers at once (instead of single boxes), but large-format cartons can force single‐box handling, halving throughput in some cells.

- Longer Reach Paths

- Tips for SMEs

- Stay under 50% of rated payload for peak cycle times. i.e. an 8 kg rated cobot works fastest with ≤4 kg boxes.

- Standardise on common carton sizes that fit your EOAT’s optimal footprint (e.g., 400 × 300 mm layers) to minimise path length.

- Simulate with your exact box specs: empirical trials reveal true cycle times within 5% accuracy, helping you forecast ROI.

Which model is best suited to my throughput and pallet size?

Match the heaviest case weight, target pallet height and required cases-per-minute (pace) to our spec table above. If two models qualify, pick the smaller for the lowest capital cost, but keep in mind any future products which will demand a larger reach or payload.

How does high product variation influence the choice or configuration of a cobot?

We will always discuss your requirements to ensure that you end up with the right palletiser solution. We will specify a model with enough headroom in both reach and payload and train you on the cobot programming, which will allow you to change box sizes or update configurations if you want. However, if you are ever considering adding a new box in the future, we are also happy to help you validate the operation before you go live in your factory.