A Practical Guide for SMEs

For most small and medium-sized manufacturers (SMEs), the dream of designing a brand-new, “greenfield” factory from scratch is rarely realistic. Tight budgets, existing equipment on crowded floor plans, and ongoing production schedules make it impractical to tear down and rebuild your factory floor.

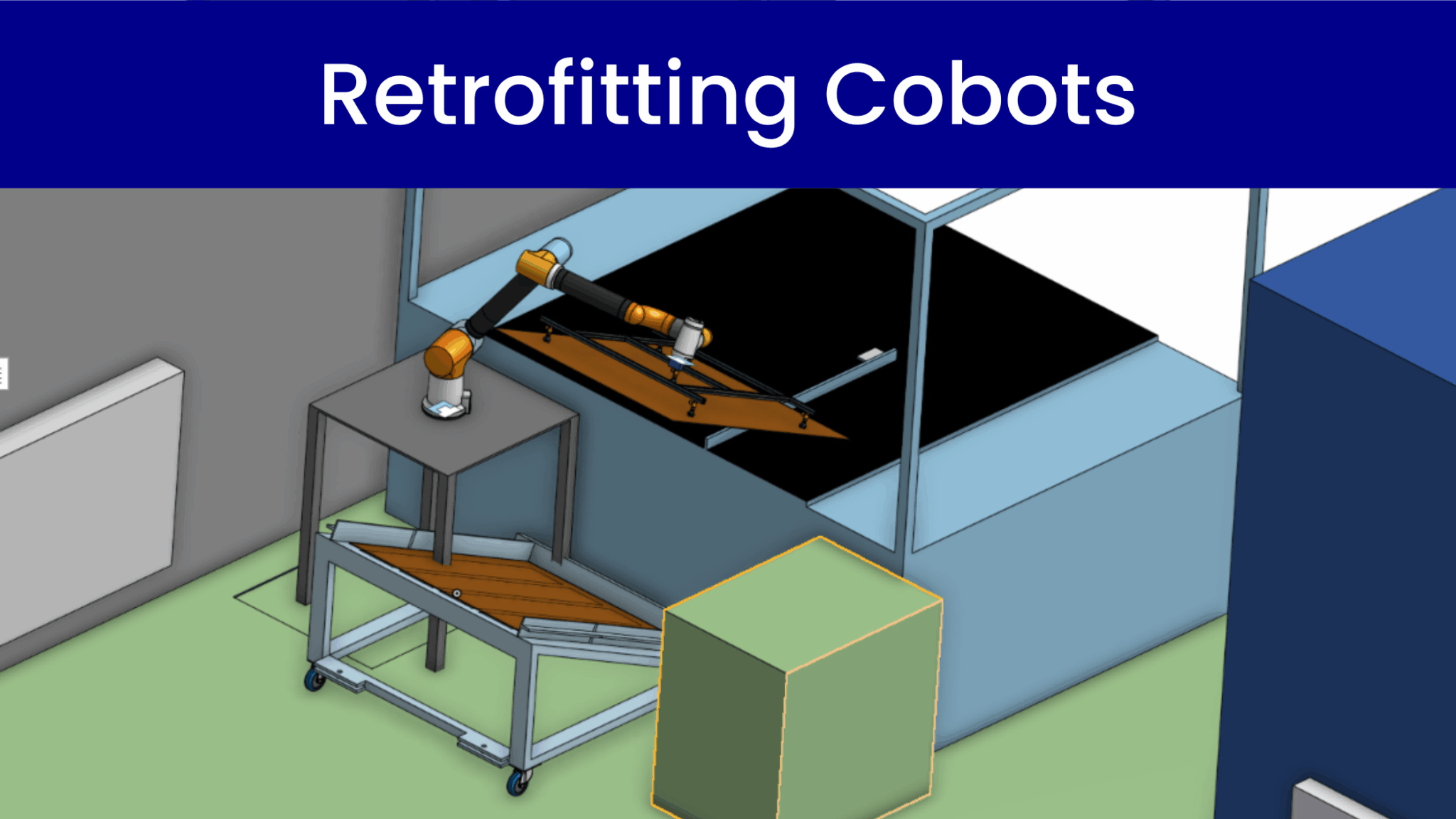

However, there is a smarter way to bring advanced manufacturing automation solutions into your operation: retrofitting collaborative robots (cobots) into your existing production lines. By focusing on repetitive but essential tasks like loading and unloading machines, simple part handling, and basic quality checks, SMEs can achieve significant efficiency gains without major disruption.

Retrofitting cobots is low-risk, flexible, and scalable, making it an ideal path for low-volume/high-mix factories producing a wide variety of products in small batches. It allows industrial automation manufacturers and managers to unlock productivity and ROI while keeping capital investment manageable.

Why Retrofit is the Realistic Choice for SMEs

Many SMEs have made a substantial investment in machines, such as CNCs, presses, laser cutters, grinders, or laser markers. These legacy machines may be unique, expensive and perfectly fit for purpose. Completely redesigning your production line to accommodate industrial robots or replacing them with newer, automated versions is not only expensive but often unnecessary.

The reality of small-batch, high-mix production facilities is that flexibility is key. Retrofitting cobots into existing lines lets companies gradually automate, starting with easy-to-automate, repetitive tasks.

The benefits of retrofit automation include:

- Lower cost and minimal disruption: No need to redesign the factory or replace existing equipment. The small footprint and flexible safety options of a cobot mean it can fit within your existing footprint.

- Faster ROI: Incremental automation means you can learn as you go and reapply lessons to future projects. Also, the smaller scope and straightforward nature of loading and unloading tasks often pays for itself within 12–24 months.

- Flexibility: Existing machines usually have a well-defined scope of work, and cobots can be flexibly programmed and integrated to handle the product within this design envelope.

For SME owners and managers, retrofit is often the most practical way to modernise operations without risking downtime or massive upfront investment.

Typical Retrofit Applications

Marking, Packaging & Palletising

Cobots can load/unload many end-of-line finishing machines, such as those that mark, engrave, or pack small batches. One of the areas of “greenfield” automation that brings a fast ROI is palletising of the final products. If this is a task you still do manually, automating it is one of the fastest returns on investment, especially with ‘traditional’ large, expensive palletising robots being replaced by the smaller footprint, reprogrammable palletising cobot.

Machine Tending (Load/Unload)

Cobots excel at repetitive machine-tending tasks. They can be added to CNC lathes, milling machines, grinders, presses, or laser cutters to handle the loading and unloading of parts. Your operators will be free from the monotonous, repetitive work and able to focus on higher-value tasks like programming, process optimisation, or quality assurance.

Part Handling & Transfer

In small-batch production, parts often need to move between multiple machines. For example, parts may go from a press to a laser cutter, or from CNC to inspection. Cobots are good at handling these transfers reliably and if the end-effector (gripper) is designed correctly, there is minimal time required during product changeovers.

Inspection & Counting

Industrial collaborative cobots can be equipped with cameras, probes, or sensors to perform in-cycle quality checks. Results can then be recorded directly into an ERP or QMS system. So, if your goal is to push further into Industry 4.0, then giving your managers access to real-time data, including yield, defects, and production efficiency, is critical

How Retrofit Automation Works in Practice

Program Selection Automation

The ability for an operator to scan a barcode or enter a works order number, gives the cobot the required information to select the correct program for itself and the machine it is tending. This reduces errors, speeds up changeovers, and ensures consistency across multiple product families.

Database & ERP Integration

If the system is integrated with a database like an ERP or QMS, the automated operations can be logged against the works orders (WOs) and the inspection results can be logged (often in real time), providing traceability and reporting without manual data entry.

Adaptive Flexibility

Cobots are easy to program. This makes them ideal for SMEs who take on new or bespoke products. As long as the new product fits within the design envelope of the machine it is automating, it can offer industrial automation advantages without the rigidity of traditional industrial robots.

Benefits SMEs Can Expect

- Productivity Boost: Machines keep running with fewer idle periods with the option for “lights out” operation.

- Consistency & Quality: Automated loading and inspections minimise defects and improve detection accuracy.

- Traceability: Direct ERP/QMS integration enables full batch reporting with data available for dashboards and other process improvement/optimisation efforts (Lean, TOC, etc)

- Labour Flexibility: Operators focus on high-value tasks instead of repetitive work.

- HSE benefits: Operators no longer have to do dangerous, cumbersome or ergonomically unsound tasks.

- Scalability: Start with one machine and expand to multiple cells as confidence grows.

- Faster ROI: Typical payback for machine tending or inspection tasks ranges from 12–24 months.

For business leaders, these benefits translate into improved throughput, reduced waste, and measurable cost savings, all of which help SME businesses stay competitive in today’s manufacturing sector.

Practical Steps to Get Started

- Audit: Identify repetitive, low-value machine-tending tasks suitable for cobots.

- Pilot: Start with one cobot and one machine to test ROI and workflow improvements.

- Integration: Add barcode scanners, vision systems, and database connections incrementally.

- Train: Upskill operators to manage and supervise cobots alongside existing equipment.

- Expand: Apply the successful retrofit cell design to other machines, scaling automation gradually.

Case Scenario: Retrofitting a Cobot Load/Unload Cell onto a Fibre Laser Cutter

Background & Challenge

An SME operated a large flat-bed fibre laser cutter (working area of 3050 × 1530 mm) to cut a wide variety of parts in small batches. Operators manually loaded the raw sheets, started the program, unloaded finished parts, inspected them, and then transferred them to the next station.

Challenges included:

- Idle machine time between load/unload cycles

- Large unwieldy sheets of raw material.

- Occasional misplacement or damage of parts

- Inconsistent inspection results

- No data on yield or defects

Retrofit Solution Overview

- Cobot Cell & Positioning

The cobot is positioned adjacent to the laser cutter with reach to cover both material feed and output areas. A fixture/hopper presents the raw sheets in a fixed, repeatable location. - Program & Order Selection Integration

An operator can scan a barcode or enter a works order, which selects the correct program within the robot and the laser. The cobot then automatically begins loading the raw material and unloading the finished components. - Load / Unload Operation

The cobot picks raw sheets from the material stack, places them on the laser table, and removes finished sheets to a staging area. Scrap material is removed automatically. - Inspection, Counting & Data Logging

Integrated vision systems detect missing or defective parts. Counts and inspection results are logged directly into the ERP/QMS system, giving full traceability. - Adaptive Handling & Flexibility

The system supports multiple programs to reduce the setup/changeover time for small-batch production. It also allows quick teaching of new part geometries for future products and bespoke offerings.

Results & Benefits

- Increased Laser Uptime & Throughput

Reduced idle time between jobs and smoother workflow. - Reduced Manual Labour

Operators focus on supervising and higher-value tasks instead of repetitive handling. - Improved Accuracy, Consistency & Traceability

Automated inspection ensures fewer defects and ERP/QMS logging provides full reporting. - Faster Changeovers / Job Setup

Barcode/ERP integration eliminates manual program selection errors. - Faster ROI

Lower retrofit capital cost allows payback in 12–24 months, depending on part mix and utilisation.

Conclusion

For SMEs, retrofitting collaborative robots into existing production lines is the fastest, most practical path to automation. There’s no need for expensive “greenfield projects”. It’s best to start small, prove ROI, and scale as confidence and business growth allow.

With the right cobot integration experts and a clear roadmap, SMEs can enjoy the same benefits of factory floor automation as the “big boys”. Retrofitting collaborative robots in manufacturing settings can deliver many of the same results as traditional industrial automation solutions and help your factory grow.

Here at OmnaTec, we help manufacturers assess their machines, identify retrofit opportunities, implement cobots, and integrate their bespoke automated solution to boost productivity, reduce costs, and improve traceability. Start your automation journey today!