Process Improvement

Optimising Your Process

There are many low-cost ways to increase the capacity and productivity of your factory. Our industrial process improvement methodologies are effective for businesses of all sizes, from one-man bands to Tier 1 manufacturing sites. Our use of production process mapping methodology, process automation and industrial process optimisation results in reduced manual labour and a subsequent increase in output.

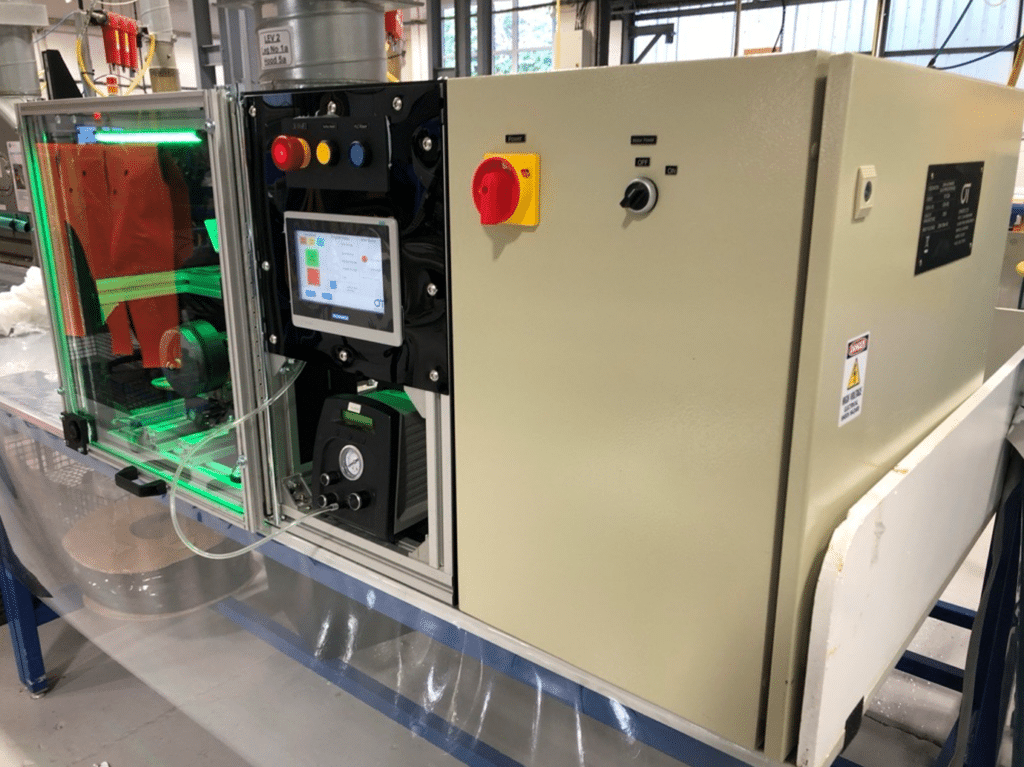

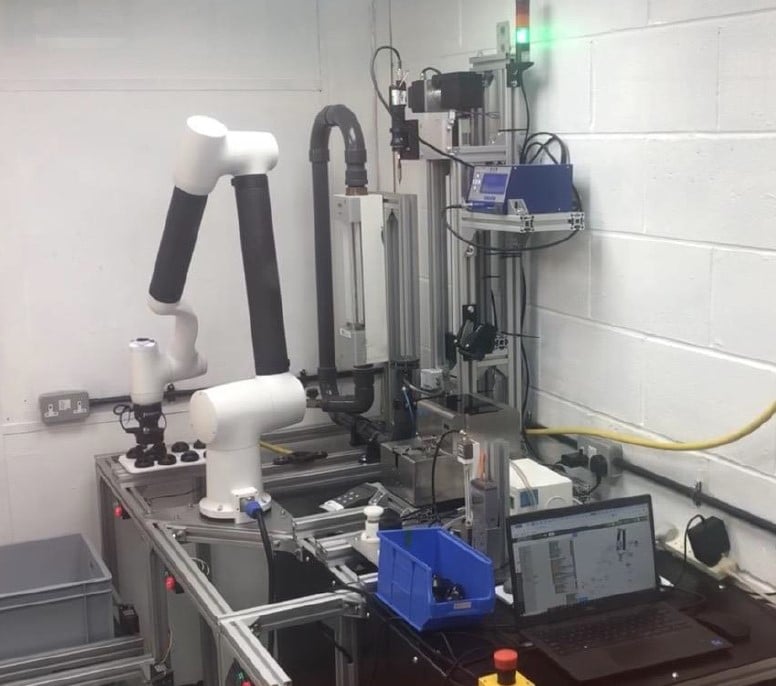

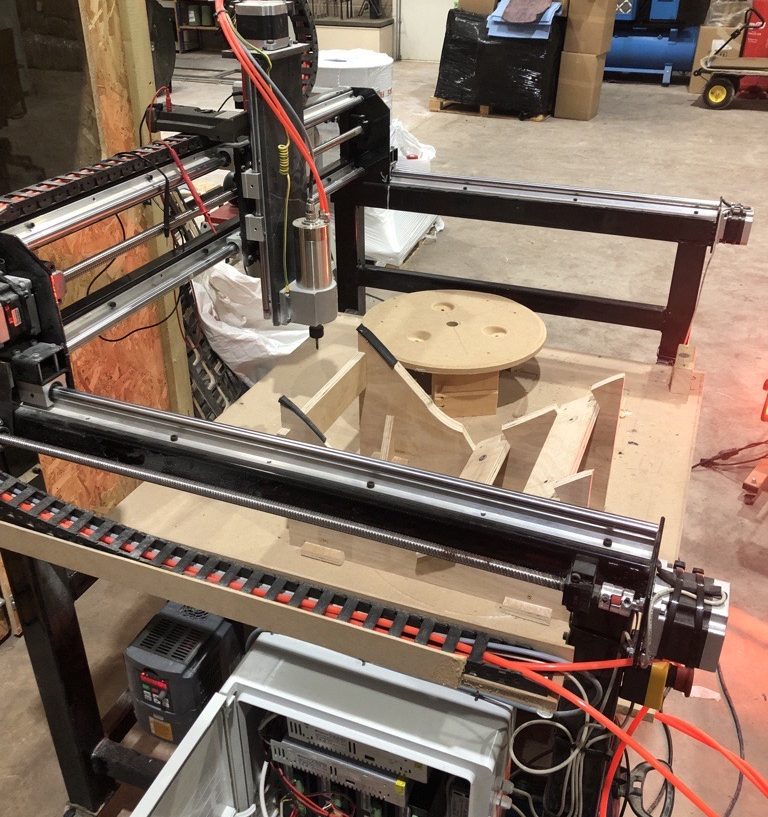

Automation of industrial production processes

Typical projects involve adopting advanced process automation through integrating automated assembly systems (including existing assembly process optimisation) and applying lean manufacturing principles. We are one of the few process automation companies that has scalable process automation and engineering solutions to meet your specific manufacturing needs.

Download Your Free Guide to Process Improvement

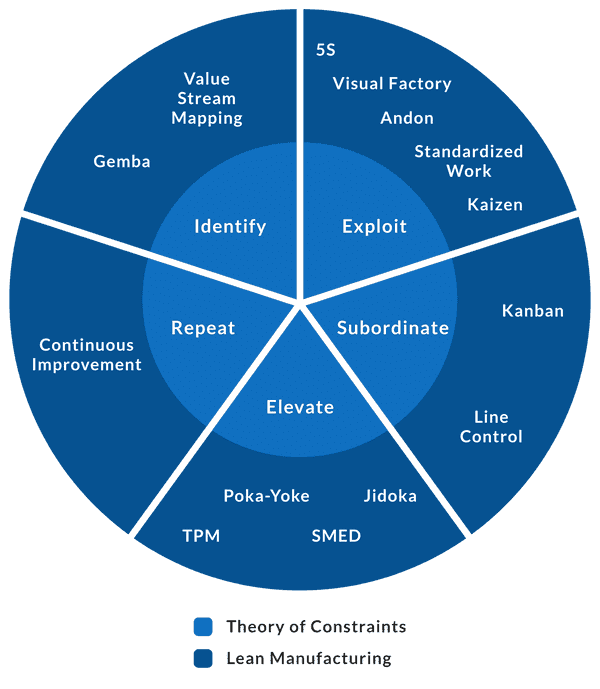

Lean

Lean is a great way to start your process improvement journey. Lean is all about reducing waste and improving efficiency.

Lean Manufacturing Tools and Principals are powerful assets to increase the throughput of your factory. Lean Manufacturing and other Process Improvement Methodologies can reduce waste and improve efficiency. If you want learn more about Lean Tools, check out the articles below:

Your Lean Production System can also be integrated with simple or advanced automation to super-charge your throughput.

Download our free infographic guide to learn how.

Theory Of Constraints (TOC)

Theory of Constraints or TOC is another great way to improve efficiencies. TOC is about finding your bottleneck and maximizing your capacity.

TOC methodology uses a four-step process to Identify, Exploit, Subordinate, and Elevate your bottleneck. This process is then repeated until the required capacity is reached.

These bottlenecks may be internal processes or external market constraints. Either way, by identifying and addressing them wasted effort is reduced and extra resources can be deployed to increase capacity. If you want to learn more about TOC, check out the articles below.

The OmnaTec Way

When you team up with Omnatec you get a partner that truly cares about your business and one that will deliver the results you need.

OmnaTec prides itself on taking a holistic and data-driven approach to your goals.

Holistic means:

- We are agnostic in terms of automation companies and systems

- We help you look at the whole operation and bring a fresh set of eyes

Data-Driven means:

- We use whatever appropriate tool is required to ensure we understand the root cause and overall flow of the solution

- We confirm the waste and throughput data to ensure the goals of any project are putting resources where they have the biggest impact.

Download our infographic to see how OmnaTec’s holistic approach can bring you the best of the process improvement methodologies and any automation solutions.

Customer Case Studies

Discover how our process improvement solutions enhance efficiency, reduce time, increase manufacturing capacity, and enhance quality for our clients across various industries.