Time: our scarcest resource

Lean Manufacturing is a methodology first brought to bear on Toyota’s assembly line in Japan in the 1950s and 1960s. They called it the “Toyota Way” or the Toyota Production System (TPS). (https://www.toyota-europe.com/world-of-toyota/this-is-toyota/toyota-production-system) They were the first to think about waste in its different forms and identify time as the most precious of commodities.

Iron Triangle

The Iron Triangle is a management tool to consider cost, quality, and time. (https://www.prince2.com/uk/blog/project-triangle-constraints) The traditional production and financial mindset is to focus on cost. The reason this thought process made sense is: low cost will result in higher margins and more profit.

The Lean mindset focuses primarily on time (make it efficiently) and secondarily on quality or production stability (keep on making it) with cost being a “pleasant” result. This article will look at the primary concern: Time

Time – only 24 hours in a day

Any process can be broken into its individual sub-steps and analyzed independently for efficiency and value. One useful metric to look at is “Cycle Time”. If the time for each individual sub-step is added up, we get the total time for the overall process and when looking at a manufacturing process, this is known as “Cycle Time”.

Cycle Time is part of the overall “Lead Time”, which also takes into account the order processing and dispatch activities in addition to the Cycle Time. The lean methodology can also be applied to the Lead time as well as any other processes. (order input, despatch, purchasing, HR, etc)

Let’s take an example:

If you have a one-person company and it takes 1 day to make 1 widget, you can make 5 widgets a week. If your average order book is for more than 5 widgets a week, you will have a backlog. The only way to clear that backlog is to hire someone else (increased cost) or to reduce the cycle time for your widget.

Assuming you don’t want to increase the costs to the business, you will need to figure out a way to increase your capacity using what you’ve got. Your widget needs to be made more efficiently. Start by analysing the individual sub-steps in your manufacturing process and breaking them into three categories.

https://www.spica.com/blog/7-wastes-of-lean

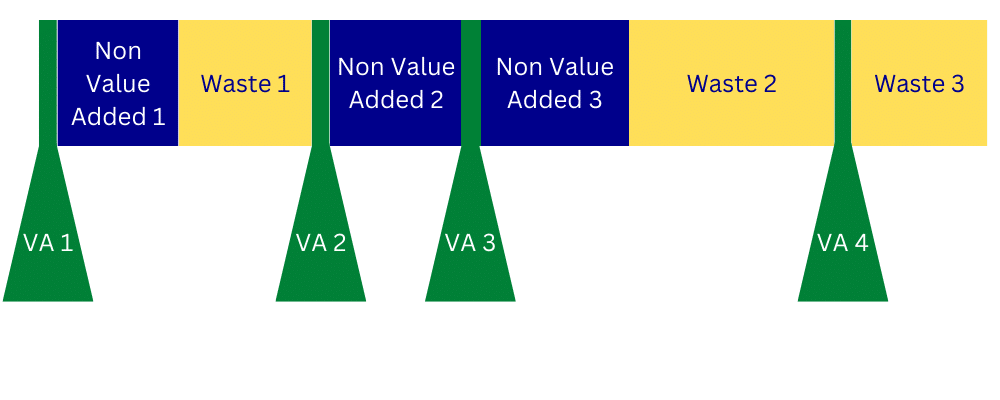

The image below depicts how these three types of categories contribute to the overall lead time.

Note: VA is Value Added

Though the image is not to scale, you can imagine how the wastes and non-value-added activities could greatly outweigh the value-added ones. The stock of components in stores, the movement of parts from one bench to another, the waiting for one process to be done before the next one can start, and the set-up time on a CNC are all examples of waste.

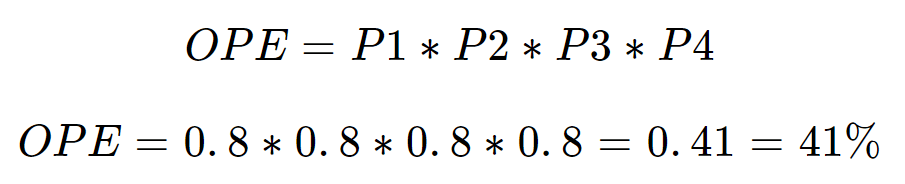

Process Cycle Efficiency

This idea of comparing the time for Value Added to Non-Value Added steps is called the Process Cycle Efficiency (PCE). It is the ratio given by the sum of all of the Value Added activities over the sum of the Non-Value Added activities and the Waste.

Note: NVA is Non-Value Added

The PCE is often less than 1%!

This is why the Lean methodology focuses on waste removal. Even if there is a 100% improvement on one of the value-added processes steps, it won’t make a dent in the total time. However, if even one waste is reduced or eliminated, the total lead time will come down significantly.

How can I use PCE?

Let’s take an example of a CNC machined component.

Total time is 4 days, 4 hours, and 7 min!

It is pretty clear that even if the machining time is cut in half and 2.5 minutes are shaved off, it won’t put a dent in the overall Cycle Time. As a result, that improvement won’t help increase your capacity. For reference, it is only a 0.05% improvement in Cycle Time.

However, if we focus on one of the wastes and we can reduce the time the components sit as billets or in inspection, we can reduce the lead time and create “extra” time within our day. In this case, a 1/2 day improvement in waste gives us a 12% improvement in Cycle Time.

What’s next?

A Lean mindset and specifically PCE are useful to help identify the sub-steps in your process which can be exploited for maximum gain. Once the process has started to be optimised and the Cycle Time improved, that “extra” time can be redirected to increased capacity or other products and processes.

In the next Lean post, we will look at the consequences of a low-waste process and the importance of maximizing the quality once the PCE has been improved. If you have any questions before then drop us a line!