Case Study:

Legacy CNC

Industry

Premium home furniture

Budget

<£15k

Task

Troubleshoot & fix a CNC router

Solution

Updated code & added manual safeguards

SMEs and automation: a difficult partnership

In this case study, we examine an example where OmnaTec stepped in to assist an SME facing precisely this predicament with a piece of their legacy CNC machinery. We helped the customer troubleshoot the issues, brainstormed some possible causes, and laid out a plan for addressing the issue.

Over the last 20 years, the adoption of automation technology among Small to Middle Engineering (SME) companies has become increasingly prevalent. These companies, driven by a desire to increase capacity and their market share, have turned to automation solutions to increase their productivity and stay competitive. This trend is only looking to continue; in fact, according to the recent Industry Insights Survey 2024 by Automate UK, 79% of their respondents, many of whom are SMEs, have reported automation growth within the last year, reflecting a broad recognition of the possible solutions CNC automation can provide.

However, as these companies have automated, they often have the problem of supporting and troubleshooting machines if key people leave or retire. This lack of in-house expertise to address issues when their automation equipment malfunctions can make manufacturers hesitant to continue to automate. Unlike large corporations with dedicated teams of specialists, SMEs may struggle to troubleshoot complex machinery, especially if it dates back years or decades and may not have the in house experience of “what might go wrong”.

Background of the CNS Solution Project

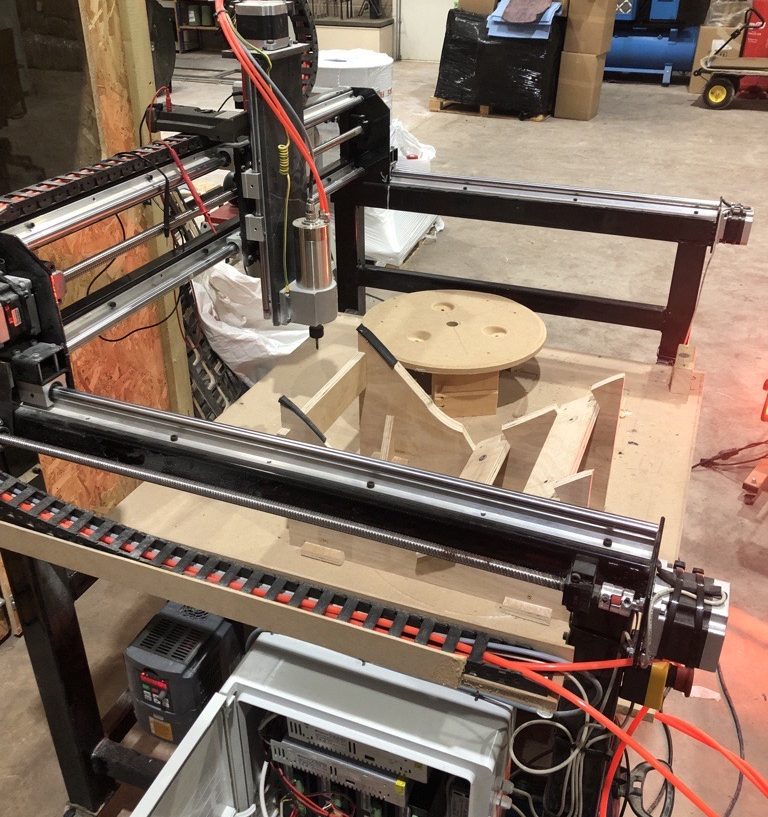

The customer was a manufacturer of high-end home goods and one of their product lines is tables and chairs made of locally sourced wool. The wool is pressed into shape and the resulting product has a significant flash around the perimeter. This flash is roughly cut off, then precisely trimmed. The items are then power sanded and finally sanded by hand. Many years ago, the customer bought a bespoke CNC for doing the rough cut. This saved them significant time for multiple reasons:

- Doing the rough cut by hand took over an hour, where the CNC could finish in 10 minutes.

- The rough cut with the CNC could cut more of the flash off, whereas the manual rough cut had to be done very carefully, so they didn’t over cut and damage the product. This meant:

- Less scrap due to errors in the manual rough cut

- Faster and easier precision trimming as there was less material to remove.

What was the problem with the current CNC system?

The machine was not performing as per the customers specification. There were a couple of issues identified, most of them intermittent. It would work ok for a few items and then suddenly a problem would arise. Some of the problems they saw were:

- The cutter would move along a path and then suddenly go off course and cut through the product.

- The cutter would bottom out on the base plate

- Cuts would appear offset, i.e. not cutting on one side, but cutting too much on the opposite side.

The customer tried to contact the original machine builder, but he had retired and was unreachable. Also, the employee who had done the original G-code programming had left the company, so they were quite stuck!

The first step is to watch and listen

Omnatec visited the customer to get first-hand information on the problems. We listened to the problems they were seeing and asked a lot of questions about when the problems occurred and what was happening. We tried to observe the problems first-hand and record the circumstances at the time. All of these things are generic best practices when trouble shooting a problem. Especially on a process you are unfamiliar with. In these types of cases Observational Voice of the Customer (OVOC) is key. OVOC involves directly observing customer behavior, actions, and interactions in their real-world setting, instead of relying solely on interviews or customer recollection. This can sometimes lead to an insight that wouldn’t have been established without first-hand observation. A good example of this is when the developers of Febreze employed OVOC and actually observed consumers using their product in their homes. They noticed a recurring pattern of people using it as a finishing touch after they completed their cleaning routines. They sprayed it on furniture, curtains, and other fabrics as a way to freshen up their living spaces and reward themselves for a job well done. This insight totally shifted the Febreze marketing strategy. Instead of positioning Febreze solely as an odor eliminator, the company began marketing it as a product that added the final touch of freshness to a clean home. This subtle but significant shift resonated with consumers, who now saw Febreze as a necessary part of their cleaning routines rather than just a solution for eliminating odors. In our case, we were looking for anything unusual that didn’t get communicated in the work process or in the operator’s description of his steps. After observing the process and discussing the findings with the customer, we made a plan for some next steps based on the likeliest culprits for their problem. These were seen to be:- Mechanical Hardware

- Electrical hardware

- Programming

The next step is to isolate

Once we had identified the likeliest culprits and observed the process, we made a plan to isolate each area or subarea to help us narrow down the problem. With intermittent problems, finding a root cause can be very difficult, but running tests on smaller areas or subsections is easier and faster. First, we replaced or removed different components of the mechanical and electrical system to see if a problem could be identified or eliminated. Though there were some questionable items, none appeared severe enough to explain the problems.

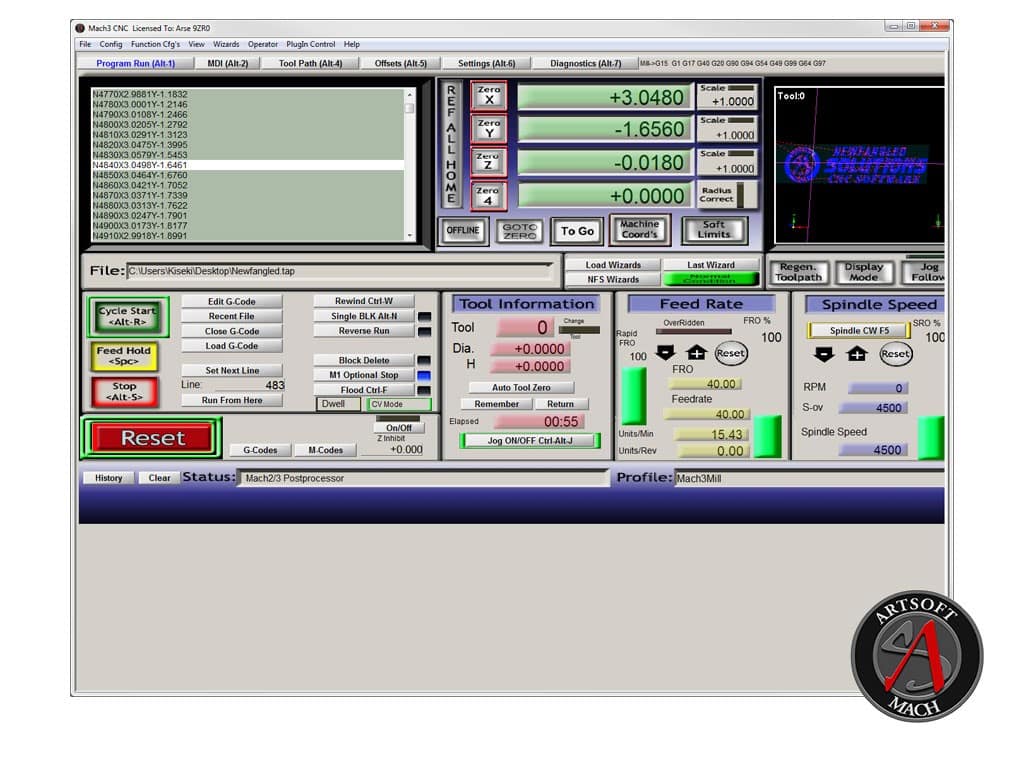

We then moved onto the programming. MACH3 is a CNC control software, it was used to run the Gcode program, and it had a number of inconsistencies in relation to local and global coordinate systems. Usually, a local coordinate system helps ensure consistency, but it appeared there were some issues with the program or controller switching between the two systems.

Fixing the problems with the CNS machinery

Due to the simple nature of the program, running it all in global coordinates was fine, so we converted the program to all global coordinates. The second issue we saw was what appeared to be a bug in the MACH3 software. In order to minimise the effects of the bug, we created a startup work instruction which should allow the operator to run the program. We also started to use some of the available features in the software like soft limits to make operation more reliable.

Conclusion

In the end the customer was up and running and happy with the results. They were happy with the new work instruction and some new knowledge to arm themselves next time if something went wrong. This case study of Omnatec’s assistance with an SME client highlights some of the methodologies and expertise used in navigating the challenges posed by legacy automation systems. As SMEs increasingly embrace automation to enhance efficiency and competitiveness, the demand for either in-house skilled technicians and engineers or partners with the necessary skill and experience grows more pronounced. Our successful resolution of the client’s predicament not only demonstrates our commitment to excellence but also showcases the tangible benefits of finding the right partners for SMEs to fully leverage the potential of their automation. Looking ahead, Omnatec remains dedicated to delivering innovative solutions and exceptional service to our clients. We are poised to meet our customers’ emerging challenges and drive progress in the industry. Through collaborative partnerships and a relentless pursuit of customer satisfaction, we are committed to shaping the future of automation for SMEs and beyond.