Case Study:

Semi-Automation as a Labour Multiplier

Industry

Personal Protective Equipment

Budget

<£40k

Task

Adhesive Application

Solution

Semi-automated Rig

High-quality manufacturer with innovation-driven growth

The customer for this project is a specialist manufacturer of personal protective clothing used in safety-critical, demanding, industrial, and emergency environments. Product performance is essential, and the consistency and repeatability of their bonding and sealing processes are critical to ensure user safety.

They have created an innovative new product that requires precise and repeatable glue deposition. The adhesive used is extremely specific to the materials and environment, but it has not previously been applied via an automated process.

Background of the Project

The new product requires a precise application of a special adhesive to ensure consistent bonding performance. Initially, at the development stage, a manual process was created using brushes. During the early production batches, this process was carried out by trained operators. Each product requires cleaning (30 seconds) and about two minutes of manual glue application.

While effective at low volumes, the manual process was time-consuming, messy, physically demanding, and the quality varied. With forecasted demand rising significantly, the customer needed a scalable solution that could maintain quality without a proportional increase in labour.

OmnaTec was engaged to design and deliver a practical automation solution that could be introduced safely into their existing production environment.

What Was the Problem We Were Trying to Solve?

The main challenge was not just speed, but also repeatability and scalability:

- Speed: Glue application time was approximately two minutes per product

- Repeatability: Adhesive quantity and placement were operator-dependent

- Consistency: The adhesive becomes tacky very quickly, making rework or secondary handling impossible

- Scalability: Increasing output would require a linear increase in skilled labour hours

- Flexibility: Semi-automation would provide the right balance of control and scalability, without the cost, complexity, and risk of fully automating an evolving process

The customer needed a way to improve consistency and throughput while retaining operator oversight and flexibility. They needed a solution that could be scaled along with the sales volume of a new product.

How Did We Approach It?

From the outset, the project was structured as a phased, risk-led development programme, rather than a single-step automation delivery. This was a deliberate decision driven by the uncertainty around the adhesive behaviour and the criticality of the glue application process.

Start with an MVP

Before committing to the design of a production machine, OmnaTec delivered a pre-project Minimum Viable Product (MVP) prototype as part of our “fail fast” methodology. The purpose of this early prototype was not throughput or ergonomics, but to rapidly test and eliminate high-risk unknowns.

This MVP phase focused specifically on:

- Glue deposition methods and mechanisms

- Nozzle and spreader geometries

- Bead size, flow rates, and pressure control

- Application patterns (circles vs helix, pitch, overlap)

- Interaction between adhesive tack time and motion speed

- Validation that changing the glue application method did not affect the glue adhesion (tested with pull tests)

By isolating these variables, we were able to test multiple approaches quickly, gather real process data, and discard solutions that were unworkable in practice. This “fail fast” methodology avoided locking in design assumptions too early and significantly reduced downstream technical risk.

We were also able to alleviate any fears that automating the glue application would invalidate their previous bond tests, as all tests matched or exceeded their previous results with the manual application.

Semi-Automation as a Strategic Choice

Based on the MVP findings, OmnaTec recommended a semi-automated solution rather than a fully automated design. Some tasks, such as product loading, unloading, cleaning, and glue preparation, were kept manual, while the most critical and variable operation, the glue application, was automated.

This approach:

- Reduced system complexity and cost

- Improved repeatability of critical tasks

- Maintained flexibility for a product still evolving

- Helped foster operator acceptance and engagement

Rather than replacing labour, the system acts as a labour multiplier, allowing operators to achieve higher output with improved repeatability.

Phased Delivery of the Production System

Following the MVP and subsequent Design Phase, the production rig project was delivered in clearly defined stages, each with test, review, and approval points:

Stage A

Stage A focused on validating the core mechanical concept, axis configuration, and basic control architecture.

The final milestone for this stage was a customer test at OmnaTec’s premises to review the system and provide feedback.

Stage B

Stage B introduced refined control mechanics, final control panel integration, safety systems integration, operator HMI, and incorporation of the customer’s Stage A feedback. This stage culminated in an on-site commissioned system.

This staged approach allowed the customer to:

- Take an agile approach and validate performance incrementally

- Influence design decisions with real operational feedback

- Prove process stability first to avoid investment in nonviable development avenues

- Retain a clear path to future enhancement or further automation

By combining an early MVP, semi-automation, and a structured phased rollout, the project delivered a robust, production-ready solution while maintaining flexibility, controlling risk, and accelerating time to value.

What was the Solution?

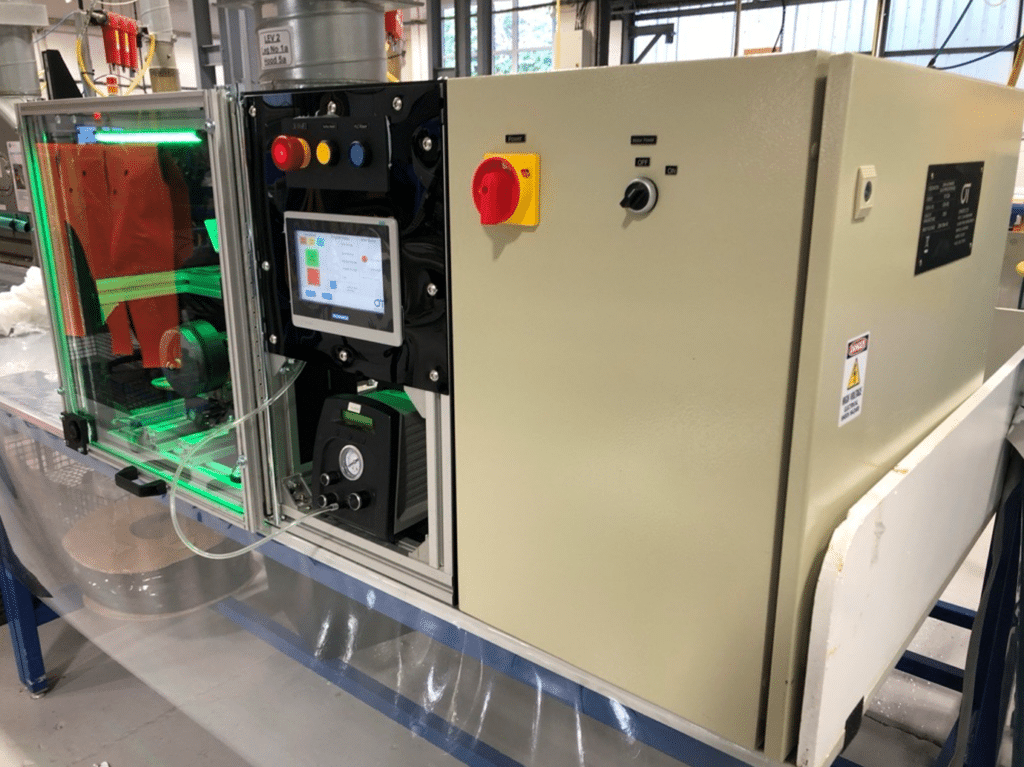

The final result was a semi-automated, bench-mounted system designed specifically for controlled adhesive deposition.

Key features include:

- Easy manual loading and unloading of product with quick-release retention jig

- Four controlled axes to generate a repeatable helical glue pattern

- Automated glue deposition with defined bead size, pitch, and coverage

- Integrated tip cleaning and purge functions to manage adhesive behaviour

- PLC-controlled sequence with intuitive HMI for operators

- Enclosed, interlocked operating area for operator safety

The system applies glue in a consistent semi-helix pattern across the product edge and bonding band, completing a full application cycle in under one minute.

Results

The system delivered measurable improvements while remaining practical to operate and maintain:

- Significant reduction in glue application time per product (from ~2 minutes down to 1 minute)

- Improved consistency of glue placement and quantity

- Reduced operator fatigue and mess

- Scalable output without linear labour increases

- Validated platform for future enhancement or further automation

By adopting a phased, semi-automated solution, the customer achieved production scalability and process consistency without the risks associated with premature full automation.

Financial Impact

As the product is new, it is hard to judge potential sales numbers, but as the introduction of a single rig could almost double the productivity, any business case based on the original manual throughput will likely improve.

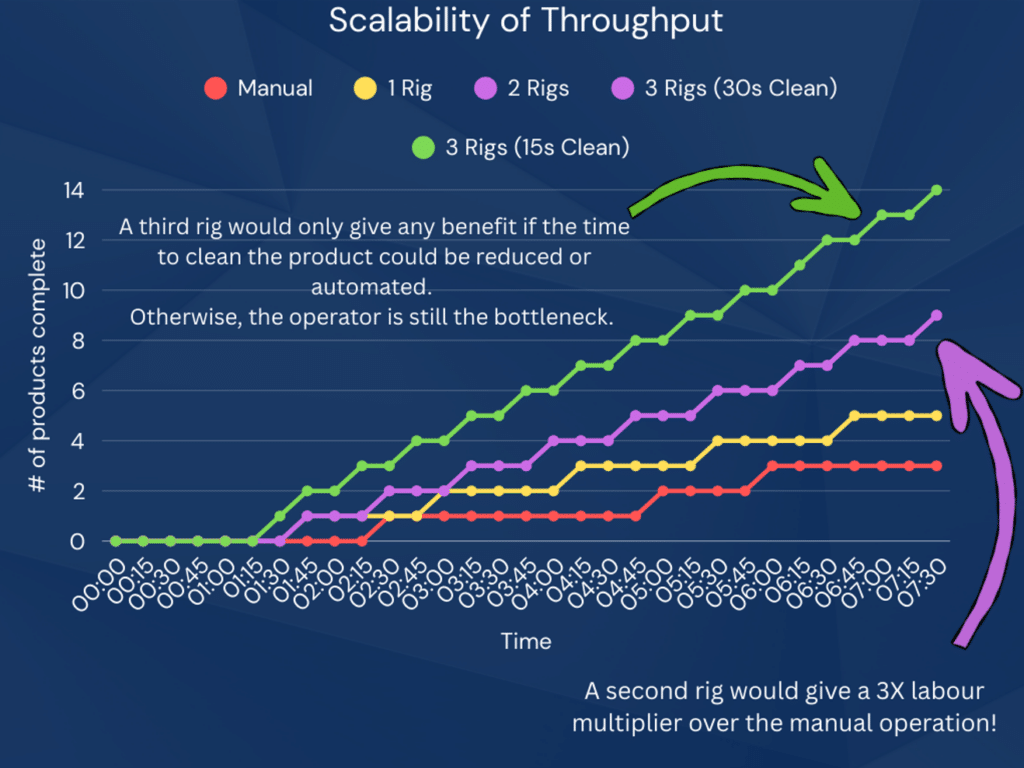

However, the real advantage is the labour multiplication possible with the rigs. As it only takes 30 seconds to clean and load a product into the rig, one worker could potentially run two machines for a productivity boost! This also assumes a balanced cell and no bottlenecks upstream, like part availability.

An option to optimise the performance would be to reduce the cleaning time or incorporate the cleaning into the automation cycle. This would help keep the automated tasks balanced with the manual tasks, and it is possible that a single operator running three rigs could produce almost 5x the product as a manual operator.

Where this is most powerful is when looking at capacity and revenue potential. If you can produce these products at a 2-5x rate, how much more market share could you take? So now the ROI is not in terms of labour cost saved, but profit earned.

Looking to the Future

With the first rig deployed, we can now work with the customer to make improvements, both small (like HMI screen layout changes) or large (adding in a cleaning operation).

Automation projects should be a partnership, starting with a staged plan/approach and with continuous improvement in mind, so we can help bring further benefits to the workforce and the company’s bottom line. This project reflects our approach as an industrial automation partner, combining engineering expertise with a collaborative mindset focused on long-term improvement.