Can’t get ahead?

Do you ever feel like your business is running smoothly, but you just can’t seem to get ahead? The Theory of Constraints (TOC) can help you understand why. TOC is a way to figure out what is holding your business back. It says that every business has at least one thing that stops it from being more successful. We call this the “bottleneck”. By finding and fixing your bottleneck, you can make your business run better and be more successful. So, let’s dive in and figure out what’s holding you back!

The Goal

If you are interested in learning about the Theory of Constraints, we would highly recommend reading “The Goal” by Eliyahu M. Goldratt. It is about a factory manager, Alex, who is trying to save his plant from being closed. It presents the essential parts of the TOC in a straightforward and entertaining way, giving a lot of real-world TOC implementation examples. It also addresses some of the difficulties you may come up against in changing the way your company thinks about efficiency, productivity, and cost.

Your Goal

One of the most important takeaways from “The Goal” is the need to change the focus of a business. In the book it takes Alex a while to reach this conclusion, but once the mindset shifts other decisions become much simpler. “The Goal” argues that the most important priority for a business is cash. A lot of businesses think it might be sales, revenue, profit, or efficiency, however, cash should be the driver. We will revisit this idea throughout the article, but it is good to start with it as it is the root of many other concepts.

Where is my Bottleneck?

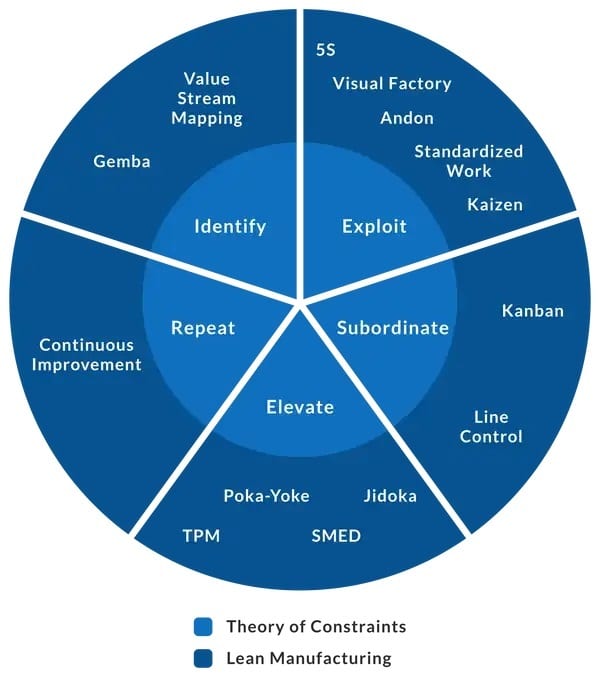

The theory of constraints uses existing production tools such as Lean, 5s, etc. to identify the bottlenecks that prevent throughput and cause a buildup of inventory. Both have a determinantal effect on cash. (See? Back again!)

- Slow throughput means long lead times and a long time to convert an order to an invoice

- Inventory buildup means cash tied up in raw materials and WIP.

The image below shows the Theory of Constraints wheel, starting with Identify. You can see how the Lean principles support the inner process circle. The two tools in the “Identify” section can be used together to help find the bottleneck. Very often a Gemba walk will identify the most likely suspects of your bottlenecked process, as stacks of inventory and WIP will be sitting around the location. For more subtle bottlenecks, a Value Stream Map (or process map) is a useful tool to map out the processes and identify where lead times are long and inventory buffers are being used.

Exploit

Once the bottleneck has been identified then you need to remove or exploit it. Most bottlenecks can’t be removed, so this means you need to use it as best you can. To do this, you need to break it down and see if there are any ways to make it better.

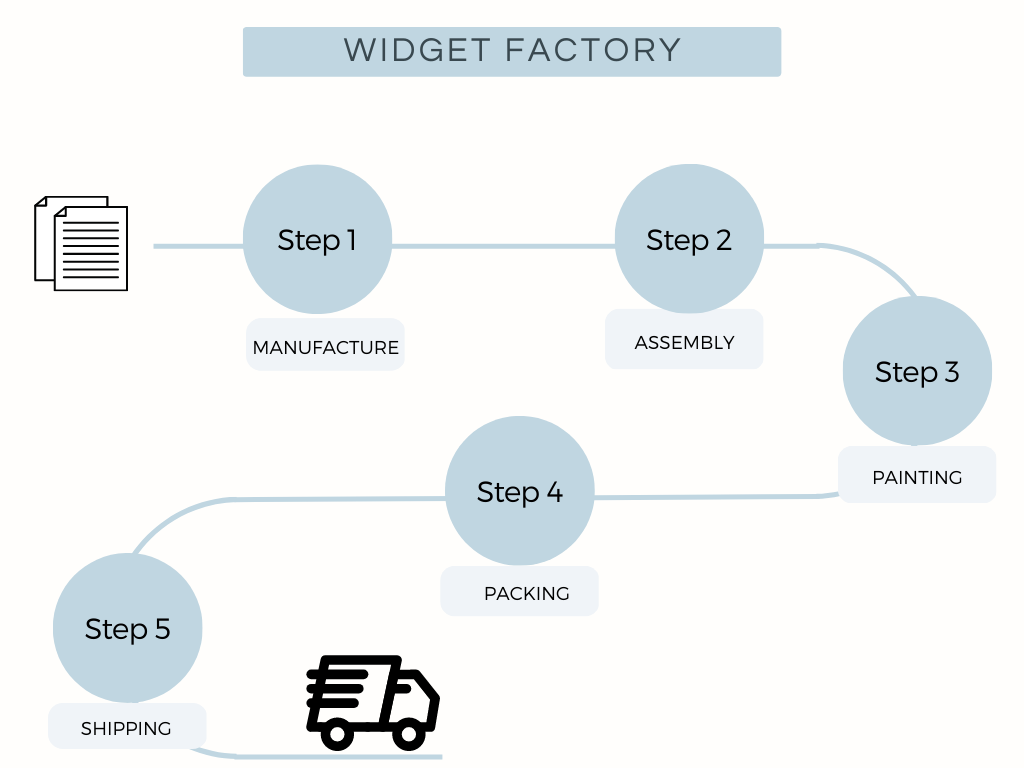

For example, let’s say a company manufactures and sells widgets. They have a production line that has a bottleneck at the painting station. The widgets are painted after they are manufactured and assembled and before being packaged and shipped. The painting station is the constraint because it is the slowest step in the process, and it limits the overall output of the factory.

This is another case where Lean and TOC complement each other. A focus on waste reduction will eliminate any non-value-added parts of the process. This will help drive a more efficient use of your resources. In the painting example, the paint might be stored on the bench instead of in a shed outside. Or a masking step could be removed to speed up the time to paint.

The other possibility once waste has been reduced is to look at automating a part or all of a process. For the painting step, this could be a fully automated paint shop or it could be a semi-automated cobot arm to make the painting faster, cleaner and safer.

Whatever method you use for exploitation, you need to keep an eye on the process as a whole. The bottleneck may move and continued exploitation of the old bottleneck will only make your problems bigger.

Bottleneck takeaway

Understanding your process constraint is crucial because, at the end of the day, it controls how much stuff your company can make. If the bottleneck isn’t running, your drum beat has stopped and you may as well shut down the rest of the line. By making the most of the constraint and using it in the best way possible, you ensure you will make more widgets and be more successful.

In the next post, we look at the importance of keeping your bottleneck running and revisit our widget factory!

Let us know if you have any questions!