Industrial Automation Solutions

Automating Your Factory Manufacturing Processes

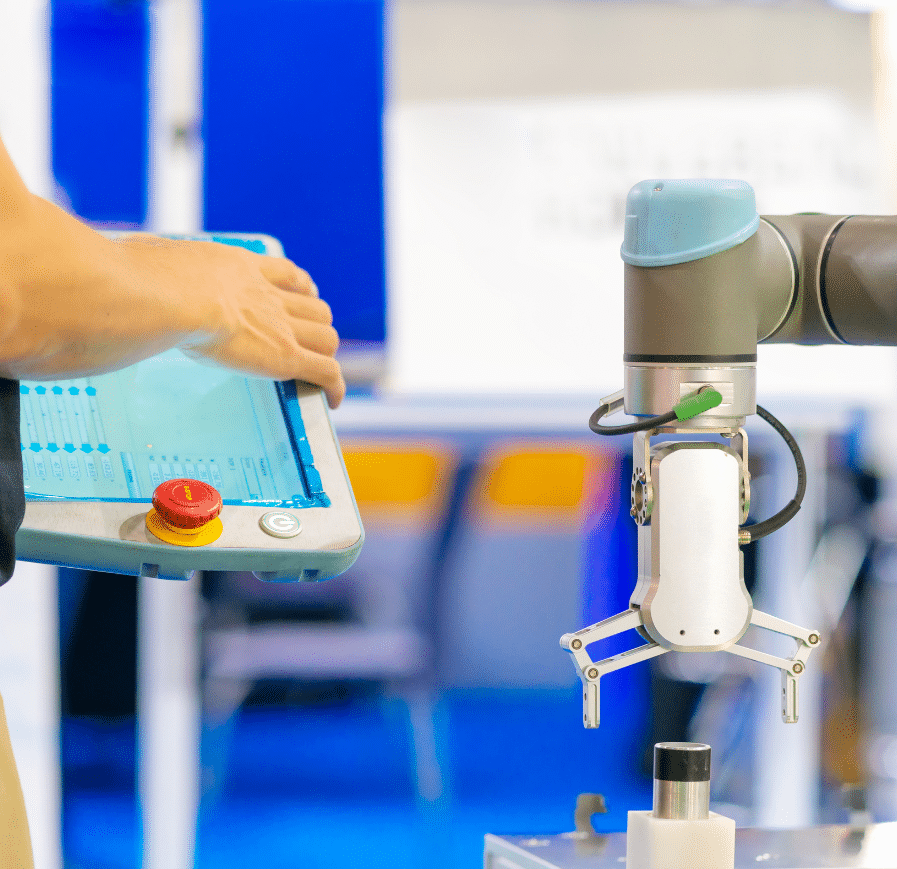

Using world-recognised component partners, we work hand-in-hand with customers to provide bespoke industrial automation solutions to help UK SME manufacturers automate. Our factory automation solutions increase production, reduce maintenance costs and improve safety.

We can help you go from the “why and how” to the “why didn’t we do this sooner”.

Download Your Free Guide to Process Improvement

Benefits of Industrial Manufacturing Automation

Manufacturing process automation is driven by many factors and each solution addresses a unique customer requirement. Manufacturing automation solutions generally address the need for:

- Increased factory capacity

- Improved production line efficiency

- Reduced manufacturing errors (Quality Control)

- Derisk dangerous tasks (HSE)

- Eliminate repetitive manual tasks (HSE)

Check out Step 3 of our infographic to learn when to automate a manufacturing process.

Securing Funding for Industrial Factory Automation Projects

Factory Automation The OmnaTec Way

- We are agnostic in terms of industrial automation component manufacturers and systems

- We help you look at the whole factory operation and bring a fresh set of expert eyes

Data-Driven means:

- We use the right tools to understand the root cause of any inefficiencies and the overall flow of the process

- Any waste reduction is confirmed with throughput data to ensure the results of any project have put resources where they have the biggest impact.

Download our Free Automation Process Infographic

OmnaTec’s holistic approach to factory automation includes using the right process improvement methodologies with the right automation solutions to get the right outcome for you.

Manufacturing Industry Automation Team

Kieron Smith BSc

Co-founder & Director

Peter Shafe BSc

Co-founder & Director

Customer Case Studies

Please take a look at some of our recently completed projects within the manufacturing industry.

Factory Automation Solutions FAQs

What is factory automation?

Factory automation is the use of a mechanical system and a controller (such as a robot) to perform manufacturing tasks with varying levels of human intervention. By automating repetitive tasks in a factory, the human labour can focus on problem-solving and innovation. It means production can be streamlined, errors reduced, and quality maintained all while keeping costs down.

What are the costs of industrial automation?

The upfront cost of industrial automation is made up of two main parts: Equipment and Development time. The equipment may include jigs, robots, sensors, controllers, conveyors cameras, safety equipment, guarding and software. The development time goes to designing a coherent solution, specifying the required equipment, integrating all the equipment, programming the controller, building the solution and testing the solution, along with any prototyping or concept testing along the way. There is also an ongoing cost of maintenance. However, though these costs can seem high, for the right project the long-term benefits of reduced labour costs, improved quality, and higher production efficiency easily justify the expense.

What benefits are there to factory automation?

Fully automating your industrial manufacturing process brings many benefits including improved production efficiency. The ability to run “lights out” and at higher speeds, boosts output and reduces lead times.

However, flexible or semi-automation is often a better fit for SMEs looking to automate. It reduces worker fatigue by automating repetitive or physically demanding tasks while still allowing human oversight for flexibility and problem-solving.

This approach is often more cost-effective than full automation, as it requires a lower initial investment and can be integrated into existing processes more easily. Additionally, semi-automation improves productivity and consistency while retaining the adaptability of a human workforce, making it ideal for small-batch production or operations requiring frequent adjustments.

Why is factory automation important?

Factory automation is important for any manufacturer because it enhances productivity, efficiency, and consistency in their factories. However, it is especially crucial for UK SME manufacturers looking to grow and be competitive. The UK’s manufacturing sector has seen its output per hour worked decline by 0.8% in the third quarter of 2024 as well as a 1.8% year-on-year decrease. When joined with the right automation partner, SME manufacturers can see huge benefits like streamlined operations, reduced costs, and improved product quality.

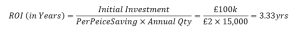

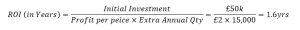

What is the ROI on an industrial automation project?

What kinds of robots or cobots are used in factory automation?

There are many types of robots and cobots used in factory automation. The main types are:

Articulated Robots – These have multiple joints, usually between 4 and 6 degrees of freedom. They are used for welding, assembly, and material handling. This group include the industrial robots used in automotive assembly lines as well the 6DOF robotic cobot arms made popular by Universal Robots, which we will touch on next.

Collaborative Robots (Cobots) – These robots are designed to work safely alongside humans, they incorporate advanced sensors to detect human presence or touch. End-of-line palletising is a common solution for cobots, and they are often used for machine tending, inspection, and light assembly.

SCARA Robots – SCARA robots typically have three degrees of freedom, they are ideal for fast, precise pick-and-place operations, assembly, and packaging.

Delta Robots – Like SCARA robots, Delta robots also have 3 DEF, but these robots are best suited for high-speed applications used in food packaging and electronics manufacturing.

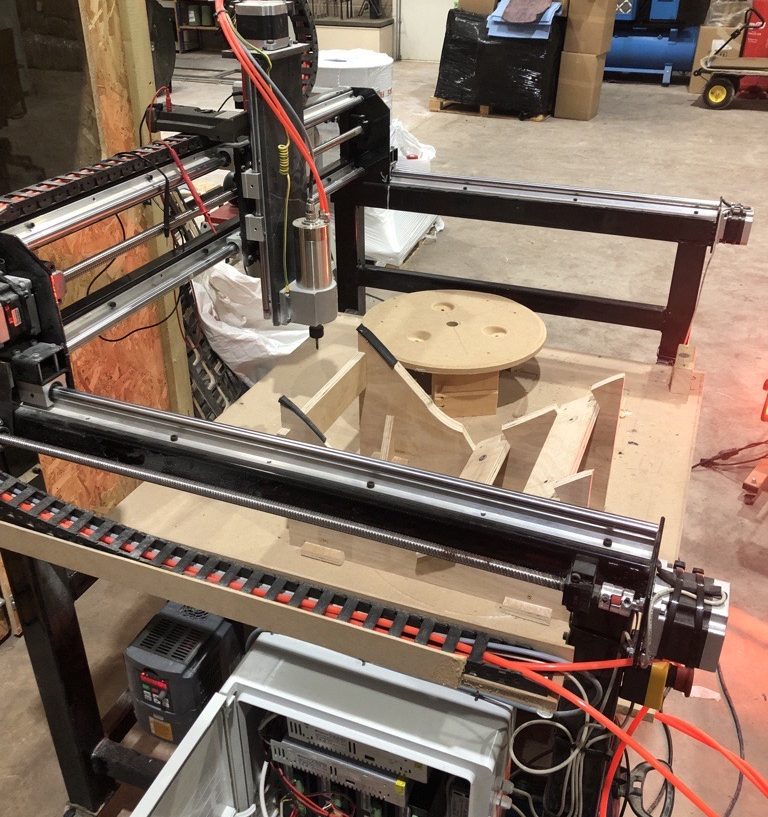

Cartesian Robots or Gantry Robot – These robots move in 1, 2, or 3 linear directions (usually the X, Y, Z axes) and are used where precise or heavy loads are moved such as 3D printing or material handling.

Can our existing machinery be adapted for automation?

Yes, your existing machinery can be adapted for automation. This would fall under Flexible Automation, allowing businesses to automate repetitive or labour-intensive tasks such as loading or unloading material. This approach is a great option for SMEs, and can help their factories move to a fully automated, lights-out operations using their existing equipment. Some good examples of automating existing machinery are CNC tending, press load/unload, and injection mould unloading, all of which can be enhanced with automation.

What are main stages in implementing factory automation?

- Scoping the project

- Development of the Concept(s)

- Building and testing the solution

- Commissioning

- Training and Handover

How long will it take to automate my factory?

Obviously, the length of an automation project is dependent on the size and complexity of the tasks being automated. It could be as short as 3 months or as long as several years. However, the overall automation strategy should be a never-ending cycle of progress and feedback. Review the factory needs, the business needs, the market needs and take your next step. Sometimes the next step may not be physical automation, but may be a data acquisition or a waste reduction project. The key is continuous improvement.

Can we semi-automate our systems?

Yes, semi-automation is a great option for many manufacturers, particularly SMEs looking to improve productivity while maintaining flexibility and keeping costs down. Semi-automated systems fall under Flexible Automation, allowing factories to automate repetitive or labor-intensive tasks while keeping human oversight for adaptability. This approach helps reduce worker fatigue, increase production consistency, and improve safety without the high costs and rigidity of fully automated systems. Examples of semi-automation include robotic work cells, cobot-assisted assembly, and semi-automated inspection stations, all of which can be integrated into existing workflows with minimal disruption.

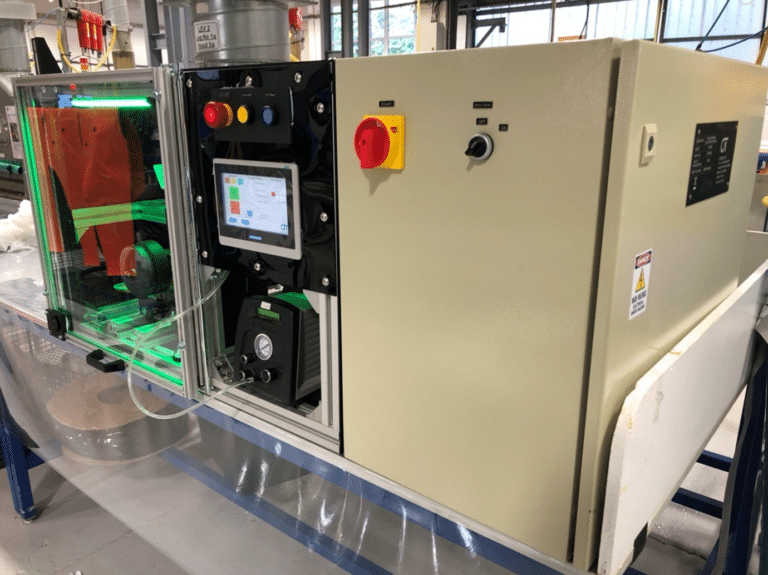

What are Control Systems?

Within the world of factory automation, control systems are the backbone of automated processes, managing and coordinating machinery, robots, and production lines. These systems monitor inputs (such as sensors and user commands) and adjust outputs (like motors, actuators, and conveyors) to ensure continuous operation.

Some of the common types of control systems with OmnaTec integrates include:

- Programmable Logic Controllers (PLCs) – Rugged, industrial processors, PLCs are a staple of most automation projects. They execute a predefined cyclic program to control machines and processes.

- Robot Controllers – These controllers handle the complex movements and positioning of industrial robots.

- Industrial PCs (IPCs) – When a controller is needed to run advanced automation software or handle complex data processing, an IPC is the right choice.

By choosing and integrating the right individual or combination of systems, OmnaTec can help manufacturers improve efficiency, reduce downtime, and ensure consistent product quality.

What are the options in factory automation systems?

Factory automation systems come in three main types: Fixed, Programmable, and Flexible Automation.

Fixed automation is designed for high-speed, high-volume production with a set sequence of operations, making it ideal for industries like automotive manufacturing and bottling plants. While it offers efficiency and low per-unit costs, it lacks flexibility and requires significant investment for retooling when product changes occur.

Programmable automation, on the other hand, allows for reprogramming to accommodate different products, making it suitable for batch production and medium-volume manufacturing. Though it provides more flexibility than fixed automation, reprogramming time and costs can be a drawback for frequent product changes.

Flexible automation is the most adaptable option, allowing manufacturers to switch between tasks with minimal downtime, making it ideal for high-mix, low-volume production. This type of automation is particularly beneficial for SMEs, as it supports product modifications, frequent changeovers, and is more cost-effective compared to fixed automation.

What are the roles of an Industrial Automation Project?

Scope: Defines the “why” and “what” of the project—your production goals, ROI targets, and facility constraints.

- You might handle simple integrations yourself (e.g., programming a PLC or mounting an off-the-shelf robot arm).

- In other cases, you’ll lean on an integrator to flesh out concepts, spec equipment from industrial automation manufacturers, and manage installation.

2. Integrator

Scope: Acts as your trusted partner to –

- Scope the problem (gather requirements, map workflows)

- Develop concepts (sketch multiple layouts or automation strategies)

- Select equipment (source from local and global industrial automation manufacturers)

- Integrate seamlessly (mechanical fit-up, software, safety validation, commissioning)

3. Manufacturer

Scope: Supplies the core hardware (robots, drives, conveyors, vision systems) from industrial automation manufacturers.

- On standard cells, they may offer basic startup support or a turnkey “mini-integrator” package.

- For bespoke machines, they’ll collaborate with your integrator (or act as one) to tailor the solution and validate performance.

Why You Need an Integrator

Why Choose OmnaTec as Your Industrial Automation Solution Provider?

Automation Expertise & Experience

Our team has over 40 years of experience in providing industrial automation solutions and process optimisation across a wide range of industries ensuring that you will benefit from tried and tested solutions. We are one of the few manufacturing automation companies specialising in the UK SME market ensuring that we are the best placed to assist you on your automation journey.

Industrial Automation Solutions & Products

OmnaTec provides a wide range of industrial automation and robotics solutions and products. Our solutions range from traditional process improvement and reprogrammable cobot integration, including palletisers, to cutting-edge bespoke automation solutions using Industry 4.0 JIT—connected solutions for your factory.

Culture & Attitude

At OmnaTec, we want our customers to be able to compete with larger competitors by leveraging the benefits of factory automation and process optimisation. By helping our customers build their products better and at a lower cost, we ensure their long-term survival and improved profits. We achieve this with our positive, can-do attitude, exploring all possibilities.

Cost-Effective Automation Solutions

We specialise in partnering with UK-based SMEs, adopting a smart approach to enable them to compete with large-scale manufacturers without the same level of investment or compromising on quality.

Nationwide Delivery and After-sales Support

Based in the south-east, OmnaTec provide end-to-end automation solutions, including everything from initial consultation to design, installation, testing and maintenance. Our commitment to our clients extends beyond project delivery. We work with manufacturers across the whole of the UK, providing continuous support for systems integration and any technical matters that arise. With the majority of support provided by phone or email, we are also happy to schedule a site visit to ensure the continued success of the project and your complete satisfaction.

Get In Touch Today

If you would like to discuss a project and would like one of our team to contact you, please choose from one of the following options: