If a picture is worth a thousand words…

Are you looking to automate a process in your factory?

Are you thinking about getting an industrial robot or a cobot to help?

Not sure which of the many solutions on the market can or will help you?

Well, if a picture is worth a thousand words, then robot programming simulation could be worth a million. Simulation is a fantastic tool to help you reduce the risk of implementing a robot.

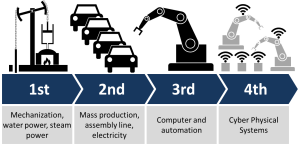

In the not-so-distant past, the world of robotics was a realm of complex software and countless hours of trial and error. Robot programmers worked tirelessly on factory floors, but now engineers and developers are harnessing the power of a virtual environment to unlock a multitude of benefits. From saving time and resources to pushing the boundaries of new robots, simulation is a crucial tool in the toolbox of those who want to implement a robot.

What is Robot Programming Simulation?

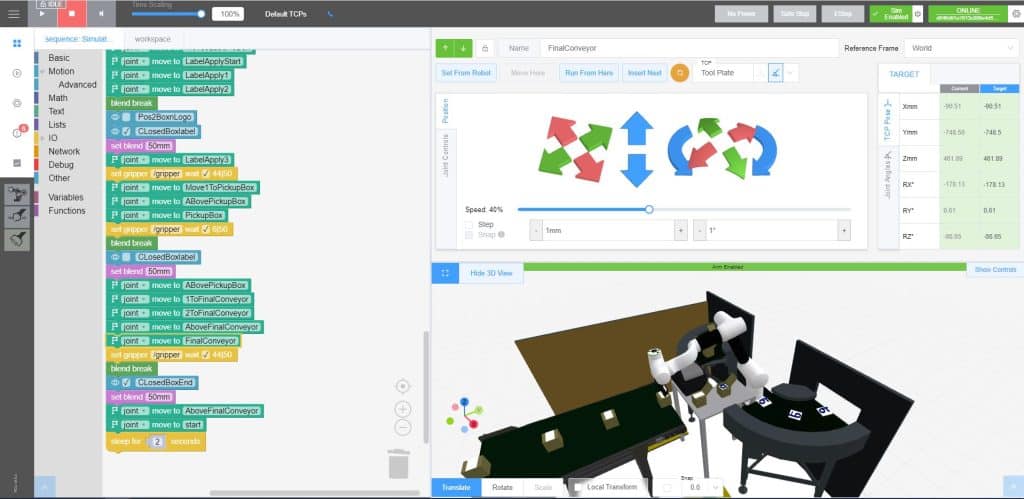

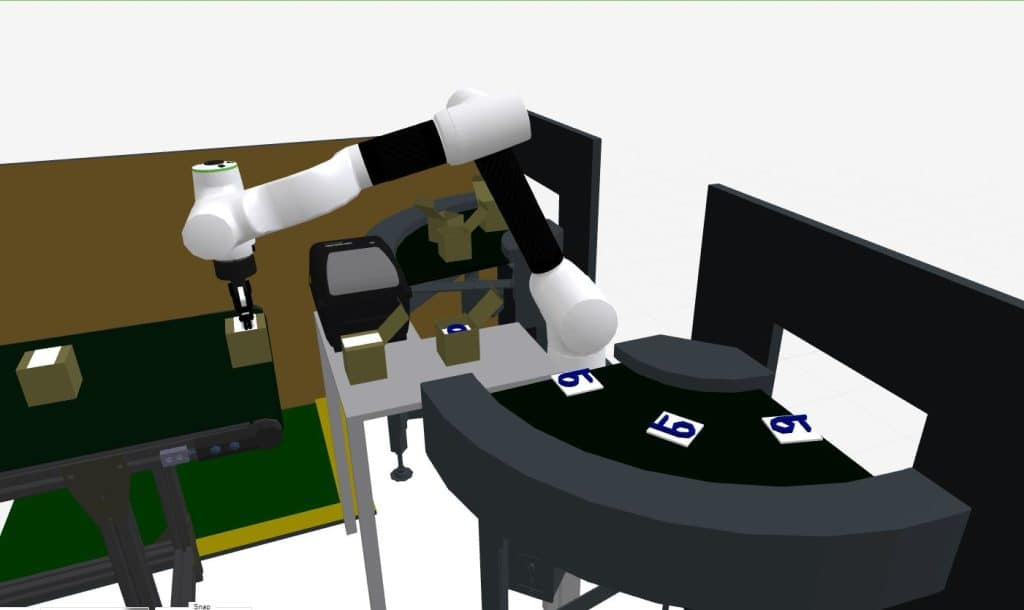

When looking to program an industrial robot, usually programmers use a combination of manual positioning, known home positions, and programmatic tweaks. However, this often requires the robot on site. Robot Programming Simulation offers a virtual environment in which to test out and program your robot. It involves the creation of a computerized replica of the robotic system. It can include the surroundings of the factory, the robot’s physical attributes, and the components to be manipulated.

This virtual environment allows engineers and programmers to test, refine and optimize the tasks it’s designed to perform without the need for physical prototypes or risking costly errors in the actual production environment. By simulating various scenarios and interactions, from intricate assembly processes to complex motion planning, simulation becomes an essential tool for ensuring the efficiency, safety, and reliability of industrial robots, ultimately reducing the risk, speeding up ROI (Return On Investment), and increasing the likelihood of their deployment.

Who needs Simulation?

Simulation can be useful at many points during a robotic automation integration project. It can also be useful to many different stakeholders on the team.

- Sales: In the quote evaluation period, a good simulation will ensure everyone is aligned with the project and demonstrate how the robot might complete the task desired by the customer. It can identify gaps between the customers’ expectations and the robot’s capabilities. It may also highlight other opportunities for the customer in other areas of their production.

- Programmers: In the concept approval phase, designers can test out different arrangements to find an optimized solution. It is also a useful collaboration tool for mechanical designers and programmers to ensure no miscommunication during the project

- Customers: Once deployed, customers can try out new applications or modified component presentation options as part of future projects and products. Improvements can be made with no risk and no downtime on the production unit as there is no need for the physical robot.

What are the top reasons to use simulation?

- Check reach: Many robot manufacturers offer a variety of models with different reaches. In some cases, they trade off payload capacity for reach or an increased reach may require an entirely higher spec model which usually brings a higher price tag. An accurate simulation should give you a good idea of how much reach you will need without overspending.

- Check Interference: As mentioned above, many robot manufacturers offer different reach models. As the reach goes up, the overall size of the unit makes collisions with the surrounding infrastructure more likely. In some cases, manoeuvres near the base of the robot become more difficult. Both can be checked in the simulation and help avoid any problems in the future with where the robot is fixed

- Check timings: Many robot manufacturers quote movement speeds which can be used to estimate a task’s total runtime. However, different joints may have slower rotational speeds and more complex programming loops may be more difficult to estimate. A simulation will give a much better estimation of the total run time expected for a program. The simulation can also be used for any future optimisation efforts to try and reduce the run time.

- Test layout options: As mentioned above the simulation can be used for process optimisation without taking a production robot offline. If the robot cell is to be rearranged or new equipment is brought in to supplement the robot capabilities the effect on timings and the optimisation of the layout can be completed in the virtual world before starting real-world testing. Things like collision checks can be done much more safely.

Simulation: I want it, now how do I get it?

When looking at an automation project and specifically a robot integration project anything which can de-risk the project will end up saving you time and money. It will also ensure that your ROI is achieved in the designated timescales.

Look for robot manufacturers who either provide a robot programming simulation service prior to purchase or have a customer-usable platform in which to try out your concepts. There are also some great third-party software which can virtualize and optimise your ideas.

If this is something, you require further details on then why not contact us to discuss further.

The images in this article were created with the Inovo Robot Simulation web interface.