Case Study:

Capacity Release with a Cobot solution

Industry

Personal Protective Equipment

Budget

<£90k

Task

Assemble & Test Subassemblies

Solution

Cobot Cell

A Tradition of Excellence with an Eye on the Future

The Component Assembly and Test Solution (CATS) is an automated cobot solution designed to assemble and test a family of assemblies in a manufacturing setting without manual labour to increase production capacity. The high quality and the demanding testing regulations of the product made the application of cobots critical for meeting automation requirements.

The customer for this project is a world-class manufacturer of personal protective equipment, including gas-tight suits for fire and emergency services teams, air-fed chemically protective suits for the petrochemical and pharmaceutical industries, as well as powered air-fed particulate suits and hoods for nuclear and pharmaceutical industries. Find out how our cobots integrated into their process to free up skilled manual labour to other critical settings.

Background of the Cobot Project

The customer is a forward thinking UK manufacturer with an eye on the future. They have invested in automation for areas of their factories where the throughput would dictate it essential to success. i.e. where the throughput required is faster than a human can do it.

For this project, the goal was a little different. The goal was less about speed and more about labour release to move workers onto other critical jobs. The tasks to be automated are fairly complex with four product variants, multiple assembly steps, and two required testing procedures. This meant that a cobot installation would be the best solution due to the combination of:

- product requirements

- cycle time

- required quantities

- budget

Cobots are well suited to a variety of tasks assuming that the end effect can be swapped or adapted for each task. Cobots cells tend to be slower as all steps are completed mostly in series with very little parallel processing occurring. This often makes them unsuitable for rigid, fast-moving “assembly line” types of applications but ideal for smaller batches with a variety of products that require a flexible approach. They can be an affordable way to accomplish multiple tasks.

Start with Lean

OmnaTec started with some observational time on the shop floor and also reviewed the components and procedures. By taking a holistic approach we were able to work with the customer to find a solution that reduced waste in the process and the cost of their investment. By working with their suppliers, they managed to get the components shipped into their factory ready to go for the automation. This reduced the waste of unpacking and then loading the components into a hopper. This actually also saved them money from the supplier as packing one of the components was difficult and expensive, with this new process the parts were preassembled and the packing cost was saved.Get Automating with Cobots

The CATS cobot solution is a robot cell which has a dozen assembly and testing tasks spread over three sections:- Tote Selection

- Tray Selection & Manipulation

- Valve Selection & Manipulation

Tote Selection

Up to three totes can be loaded, to give the cell a capacity of almost 550 assemblies without human intervention. This allows lights-out running if desired.Tray Selection & Manipulation

The cobot finds and selects the correct tray within the selected tote and moves it to a positioning jig. The system can detect and handle partially filled totes and adjust accordingly.Valve Selection & Manipulation

Each Valve is picked from the tray and follows the same process- Threaded onto test #1 jig

- Screw is inserted

- Torque driver screws in screw

- Test #1 is run

- Assembly is moved to test #2 jig

- Test #2 is run

- Pass completed assembly to hopper

Equipment used

The CATS project used

- Cobot – six axis Inovo Cobot

- Extended I/O – Beckhoff Modules

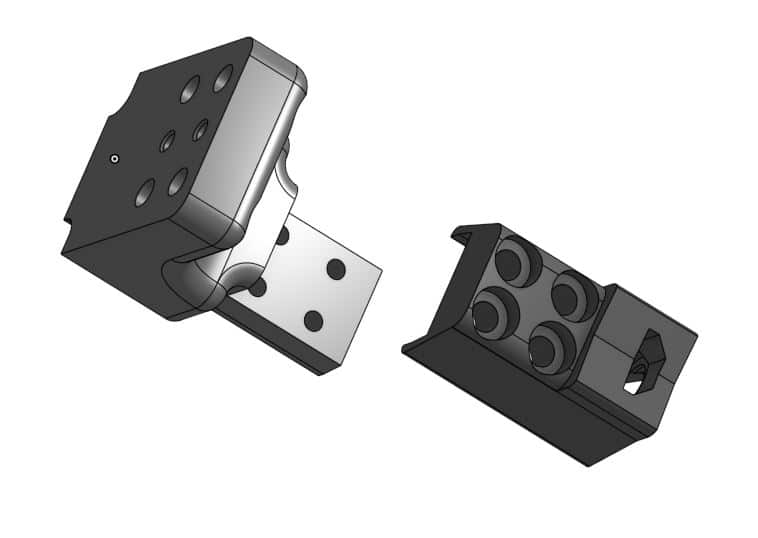

- Gripper – Robotiq Hand-E

- Gripper fingers – Due to the multiple types of items to be picked and lifted, custom fingers were required. These were designed fingers to allow for selection of:

- Trays

- Assemblies

- Screws

- Adaptors

- Screw Presenter – There are very few screw presenters on the market that can handle the length of screw required for CATS. Omnatec selected the Delta Regis DRFF-530 to accomplish this.

- Screwdriver – Kolver NATO and controller

- Keyence Laser Safety Scanner

- Multiple custom designed Jigs produced with either 3D printing, CNC plastic, Injecting moulding

Results of Cobot Integration

Cobot Project Success

OmnaTec ran a development and prototyping phase to confirm the design of the custom fingers, jigs, adaptors and feasibility of all key robot tasks. OmnaTec also refined and updated the project specification as the customer identified potential improvements to process reliability during the commissioning phase. CATS is completely compatible with all four variants with no physical tooling changes and a single user input. This means different assemblies can be run each day (or even more frequently) while only requiring removal of finished assemblies and loading of the new components. Also, the easy-to-use, drag-and-drop “whiteboard” methodology of the Inovo programming will allow the production staff to troubleshoot and refine the program if required in the future.

Financial Impact

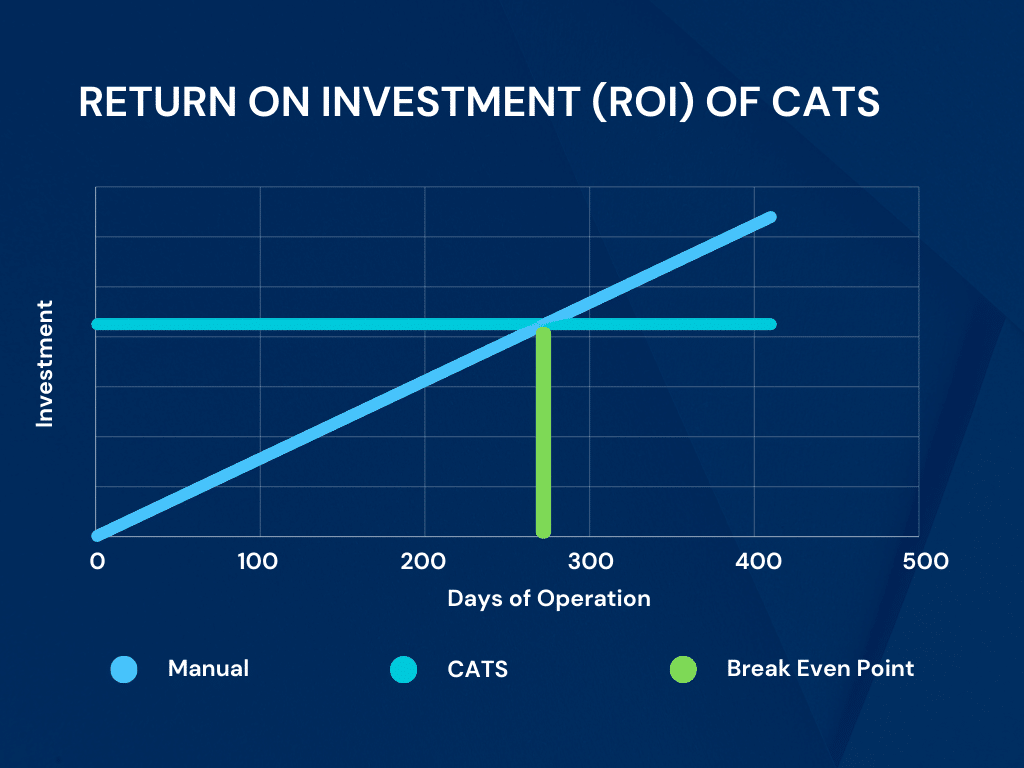

Previously, the assembly of 550 assemblies would have taken a worker almost an entire shift to complete. With the CATS making those assemblies instead, the employee can be repurposed into other crucial areas of the business. Over the course of a year this would equate to hiring another person into the business. The return on investment for this project was under two years!Looking to the Future

The customer is a long-established company making a reliable product with an innovative approach to manufacturing. CATS was designed to reflect these company values and allow for future development of the cell. OmnaTec’s holistic process-driven approach and commitment to customer satisfaction were key to the project’s success.