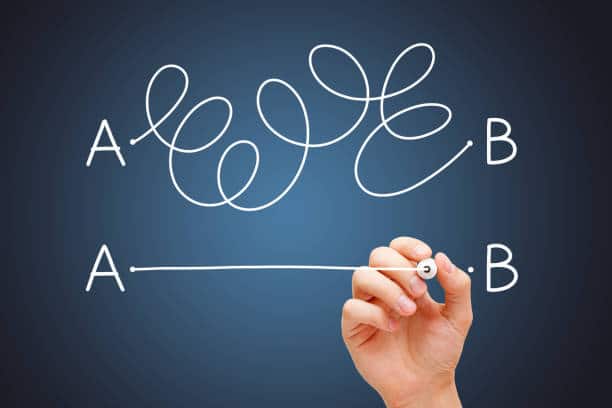

Cut through the noise and focus on what truly matters.

In a world that gets more complex by the day, the mantra “Keep It Super Simple” (KISS), also known as “Keep It Simple, Stupid”, holds more implication than ever. This simple yet profound principle reminds us that simplicity is often the key to success, clarity, and efficiency in both our personal and professional lives.

In this blog, we’ll explore the power of simplicity and how embracing it can lead to enhanced productivity and increased output.

What is KISS?

The term was first used in the US Navy and is thought to have been coined by Kelly Johnson, who was the lead engineer at the Lockheed Skunk Works. Johnson told the designers at Lockheed that their designs should be simple enough to be repaired by a man in a combat situation with only some basic mechanic’s training and simple tools. If their products weren’t simple and easy to understand, they would not only cost lives but also quickly become obsolete in combat conditions and thus worthless.

The goal of the KISS principle is to remove complexity and provide a robust solution to the problem or task. When you have a design which cannot be simplified further, but has all the required functionality, you have the simplest design or process possible.

Who should use the KISS principle and Why?

The KISS principle can be beneficial for a wide range of individuals, organizations, and situations. It’s applicable across business, technology, design, communication, problem-solving, and more. Let’s look at the manufacturing industry and how the KISS principle is used to simplify processes and solutions. you can often enhance output in several ways, but we shall focus on the product design, manufacture, resource aspects and business strategies.

Product Design

Designers who follow the KISS principle are likely to design products that are less complex and easier to build. This can improve product or service quality by eliminating unnecessary features or steps that can introduce defects or errors. These products tend to be simpler products which can be more appealing to customers. They are often easier to use and understand, leading to higher customer satisfaction.

One example of this is the Apple iPhone which overtook Blackberry within 5 years of its launch. This was mainly down to its simplicity in use and ease to setup.

Processes & Production

Engineers who follow the KISS principle in the production environment will benefit from quicker lead-times due to simplicity. When processes are straightforward, there are fewer bottlenecks and delays, resulting in faster delivery times. If bottleneck or delays do occur, they can be resolved quickly.For further information on production bottlenecks read our blog on “What’s My Bottleneck?”.

Simplified systems are often easier to respond to new challenges or opportunities as they can be scaled up or down, modified or upgraded in line with the business demands. This flexibility can enhance overall productivity, sometimes at minimally cost to the business.

Output is also enhanced due to improved maintenance as production downtime can be reduced, preventing issues causes delays and additional costs to the business. Simple systems are often easier to maintain and when issues arise, if there are fewer steps or components, it’s easier to identify and fix problems

Resource

People are the most valuable asset to any business so utilizing them to their full potential is essential. Simplicity makes it easier to train new employees. They can quickly grasp the basic processes and begin contributing to production sooner. Complexity can introduce health and safety risks, as there are more opportunities for errors or unexpected issues. Simplifying processes can reduce these risks and protect your resource.

Business leaders and Managers

KISS can be applied to streamline processes, reduce operational costs, and improve overall efficiency. Simple business strategies and models can be easier to execute and understand.

At Omnatec, we use the KISS principle in everything we do. See how we as a partner work in our blog “How We Work – Omnatec”.

When is simple too simple?

“Keeping it simple” doesn’t mean oversimplifying to the point of sacrificing necessary functionality or robustness. The key is to strike a balance between simplicity and meeting the requirements of the task at hand. Additionally, what constitutes “simple” may vary depending on the specific context, industry, and goals of production. It’s essential to carefully assess the situation and find the right level of simplicity that enhances output without compromising quality or functionality.

In the example below, you can see the same 5 data points plotted with three different “lines of best fit”. A line of best fit should help engineers describe and analyse the data. The line in the first graph fits perfectly but requires a 5th order polynomial and the third uses a linear regression and fits pretty poorly. The second graph only uses a 2nd order polynomial (ax2 + bx + c), which does a great job correlating to the data. This is what is means to be simple without compromising functionality.

How does KISS help with Optimisation?

There are many lean principles used in manufacturing, but the KISS principle can also be a valuable tool for process optimization in various ways to reduce waste, improved consistency, control and reduction of costs.

Complex processes may result in waste, whether it’s in the form of time, resources, or materials. By simplifying, you can reduce waste and improve resource utilization. This will also improve consistency because they have fewer variables and fewer opportunities for errors. Consistency is crucial in optimizing processes for quality and efficiency.

With improved consistency it is easier to monitor and control because there are fewer variables to track. This allows for more effective oversight and the ability to quickly identify deviations or issues.

All these results in cost reduction and improved supply, which ultimately results in achieving the goal, improved cash position.

How does the KISS help with Robotics and Automation?

The KISS principle can be highly beneficial in the context of robotics and automation for several reasons:

- Ease of Implementation: By keeping the automation process simple, you reduce the complexity of programming and configuration, making it easier and faster to implement. Automate sub-assemblies first, gain knowledge and then look at a single automated solution.Reduced Error Rate: Simple automation workflows are less prone to errors and glitches. Complex automation systems can be challenging to troubleshoot, leading to costly downtime.

- Faster Deployment: Simplifying the automation process allows for quicker deployment of robotic systems. This is especially important in industries where rapid adaptation to changing demands is necessary.

- Lower Maintenance Costs: Simple automation systems are typically easier to maintain. Routine maintenance, upgrades, and repairs can be performed more efficiently, minimizing downtime.

- Scalability: Simplicity in automation design makes it easier to scale up or down as needed. You can replicate simple automation solutions across different processes or tasks, adapting to changes in production requirements.

- User-Friendly Interface: For operators and technicians working with robotic automation, a simple and intuitive user interface is essential. It reduces the learning curve and makes it easier to interact with and monitor the robotic system.

- Cost Efficiency: Complex automation solutions often require significant investment in terms of both time and resources. Keeping automation simple can lead to cost savings in development, implementation, and maintenance.

- Improved Adaptability: In rapidly changing manufacturing or production environments, simple robotic automation can be more adaptable to shifts in demand or changes in processes.

- Safety: Simplifying automation systems can enhance safety by reducing the potential for unexpected or unpredictable behaviour in robots. Safety protocols are often easier to design and implement in simpler systems.

- Quick ROI: Simplicity in automation often leads to a faster return on investment (ROI). By reducing the complexity and cost of implementation, you can start realizing the benefits of automation sooner. Details of automation ROI can be found in our previous blog “Introduction to Return on Investment (ROI)”.

As discussed above, it is important to balance the level of simplicity in robotics and automation with the specific requirements of the tasks being automated. Some tasks may inherently be more complex and require advanced automation solutions. This would result in a complex background process, but the end-user interface could be simplified.

Therefore, a thoughtful and tailored approach to applying the KISS principle to the automation solution is essential to ensure that it enhances efficiency and productivity without compromising functionality.

What’s stopping you from using the KISS principle?

The KISS principle is a versatile which can be applied by anyone looking to improve efficiency or effectiveness. While the principle is simple enough to use, there can be various obstacles to prevent you from fully implementing it. Here are some common barriers:

Complexity of the Task: Some tasks or projects are complex due to their nature. Breaking these down into simpler section is a good idea, but keep in mind that excessive simplification may be counterproductive. Balancing simplicity with the complexity of the task is crucial.

Lack of Understanding: If you don’t fully understand the problem or task at hand, it can be challenging to simplify it

Resistance to Change: People and organizations may resist change, even when it’s clear that simplification could be beneficial. There may be a fear of disrupting established processes or routines or even the fear of their position being

However, it’s essential to adapt the level of simplicity to the specific context and goals of each situation, as overly simplistic solutions may not always be suitable.

“Keep It Simple, Stupid” reminds us that simplicity is not a sign of ignorance or laziness; it is a deliberate choice to cut through the noise and focus on what truly matters.

If you’re looking to simplify a process, then why not contact us to discuss further.