Where should you start?

OmnaTec had a great LinkedIn Live Panel last Wednesday with some great discussion around Automation vs Optimisation. I thought I would summarize the discussion here and highlight some of the interesting takeaways.

ConeX Portal Supplier Session 21 – Automation vs Optimisation #UKManufacturing

Our panel members were:

- Peter Shafe – OmnaTec – Omnatec.com

- Adam Payne – New Way Growth, FactoryIQ, TCMUK Limited – https://www.newwaygrowth.com/

- Ben Rotheray – The Value Engine – https://thevalueengine.co.uk/

- Sam Baynham – Conex Portal – https://www.conex-portal.co.uk/

- Steve Murphy – Six Sigma Black Belt, World Class Manufacturing – https://www.linkedin.com/in/stephen-murphy-3aa550/

Sam started with a quick introduction to the Conex Portal which if you want to know more about head over to the “FAQs” section of the site and check it out! After that we dove right in…

Diving right in

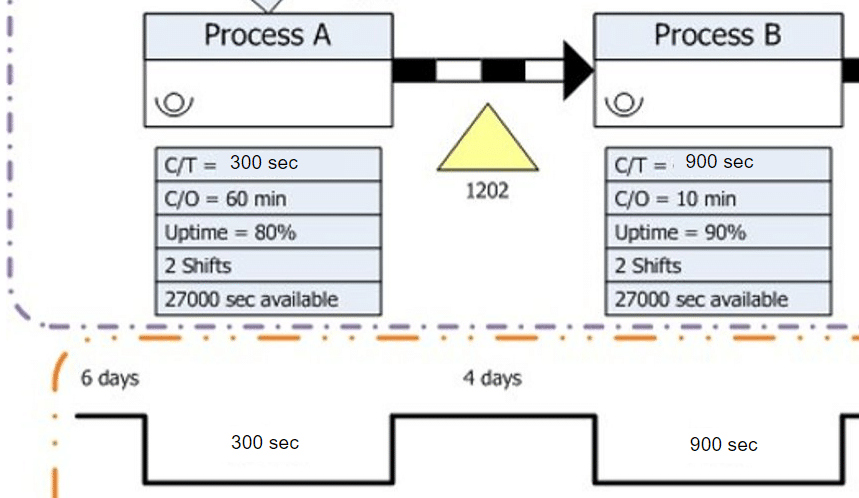

We started by looking at a small section of a Value stream Map

(https://en.wikipedia.org/wiki/Value-stream_mapping#/media/File:ValueStreamMapParts.png)

By DanielPenfield - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=28553995

In this example there are two processes:

- The first being a manually run CNC operation

- The second being a regulatorily required inspection step.

One of the first take aways was the time for the second inspection operation. (900sec!!). Some of the questions which were asked included:

- Why can’t this be shortened?

- Why can’t it be moved closer to the operation?

- Why can’t the inventory held before the step be reduced?

N.B. In this particular example the length of time was purposely long. You could imagine this being a very realisitic time for an NDE (Non-Destructive Examination) type of inspection. This might be required with certain measurements taken and recorded by an authorized inspector, all of which is on top of the internal inspection which might already be occuring as part of the first process. There might be an opportunity for automating a step if it can’t be reduced or eliminated.

This is a good example of one of our first takeaways: The importance of understanding the customer requirements as the solution might be some straightforward optimisation steps or it could be ripe for some automation to reduce the time and reliability of the inspection, it will depend on the process as a whole (More on that later! 😊).

What Mistakes to Avoid?

Next, I asked if there had been any examples where our panel members had seen some mistakes made, such as being focused on automation when optimisation would have been better or where optimisation was the preferred option and in actuality an automated solution would have been better?

Adam had a good example of machinists and manufacturers who were very focused on process time and were very interested in automating processes and speeding up cycle times. Steve related that speeding up process just for stock to sit on a shelf was waste of time and energy.

Ben brought the discussion onto one of the most important ideas we discussed which is to ensure everyone working on a project understand the whole end-to-end process and not to get to focused on one subprocess, or one department or one solution. Keeping an eye on the value being brought with any improvement or change helps ensure that the processes will be improved.

What is Value?

At this point we discussed what value means to a customer. Very often value equals more cash in the business and not having it stuck in excess inventory, but it is also tied into the mistake we discussed right before. Focusing on a per piece cycle time improvement may give the appearance of a cost saving, but that machine probably will still be running and that operator will probably still be paid whether they are working on this job or another. What automation and optimisation really bring to a businss is capacity increase. This capacity allows the business to make more and to sell more. Once again bringing more cash into the company.

Where is Automation Key?

We then looked at some places where automation is an important tool in process improvement strategies. Specifically, areas such as:

- Improving repeatability and consistency of the product. I.e., done the same way every time.

- Quality control, taking the human element out of the production, logistics, sales environment can improve the quality seen by your customers

- Regulatory changes which make old manual ways impossible. (Such as tightly controlled tolerances)

- Processes with high risk to operators which can be mitigated with automation

Steve had a really good example of wafer fabrication. Dipping the wafers in acid was part of the manufacturing processes and this step was followed by a wash step. The time between the two steps significantly affected the performance of the wafer and Steve found that they got a statistically significant improvement in reliability when the processes was automated.

Where is the best area to be increasing capacity?

Ben identified that as we enter an environment where staff wages are going up and are harder to find it makes the argument even stronger to use your employees in the most efficient manner and automate processes to free them up. The advantage of working with experts on process improvements is that we can look at the whole process and give manufacturers a prioritized list of areas where automation will be most beneficial.

Though we were talking about manufacturing processes for most of the discussion Adam highlighted that there are three measures contributing to the effectiveness of most businesses

- Overall Logistics effectiveness

- Overall purchasing Effectiveness

- Overall equipment Effectiveness

Those three times together give us overall supply chain effectiveness and there are many areas we can delve into for automation including Marketing, logistics, sales, Self-driving trucks! Again, it’s all about the big picture and any increase in productivity is an opportunity for increased capacity which allows the possibility of increased sales.

I talked about a manufacturer who automated a step of an assembly process after ensuring a fairly well optimised SOP existed. The low hanging fruit had been picked and this automation allowed the total assembly lead time to be cut by 50%. This allowed twice as many products to be built which supported the sales team to win more business by confidently saying to the customers “yes, we can meet that order with a fast lead time”. Adam believes this is part of the crucial understanding of your takt time. This allows a customer focused method for sales and process optimisation

What keeps you up at night?

Sam asked “How do you pitch it to manufacturers who are overwhelmed with the everyday activites that these process improvements will bring them some help in their business?”

Adam: There is something that is keeping them up at night, some major issue, but you have to understand the whole process. Asking what your customer demand is and what’s your available time? Figuring out how many you need to make each minute helps drive home if the capacity is enough.

Peter: Most customers tend to have an idea of where their problem is and where they need help. Worst case is someone who has done an Adam capacity calculation and recognized that their order book is going up and the capacity isn’t enough to keep up with it. Optimisation options tend to be faster ROI and helps get quick wins which helps build momentum and give manufacturers some breathing room. In all cases though a thorough understanding of the whole process is crucial. Do we automate a process to improve quality and eliminate rework or do we put some basic manual controls in place to help catch them in situ?

Steve: I like to focus on Six Sigma and defect reduction, and I like to talk to the engineers and asks for 10% of their time. If that extra 10% can be focused on value added customer work, their work week will see vast improvement in “capacity”. Teaching engineers to manage their time allows them to be more productive in the future. This was a “quick win”, which grew in the future.

Sam highlighted the LinkedIn Post with Elon Musk’s “rules for meetings” as a way to improve the productivity of the workday.

How to get started?

Sam asked how to spot some of the quick wins:

Many of the answers from Adam and Steve were focused on the crucial step of looking at the whole process and not being sucked into looking at a single step in the process or a “shiny new automation toy”. Low cost, high impact solutions give a great bang of the buck and can help build momentum as along as the change management of the process improvement is there and we try to prevent back sliding into old processes. Once these low-cost options are embedded, then the options for automation can become more obvious and much more fruitful.

We wrapped up with a few other questions from the comments, but I wanted to summarize the key takeaways below.

Key Takeways

The most important takeaway is the title of the panel.

We will not be successful if we think of it as Automation “versus” Optimisation. Only by looking for solutions wholistically can the best option for improvement be found.

- Each Manufacturer is Unique and their business and the whole process needs need to be understood

- Any process improvement is not a cost reduction – rather a capacity increase, which leads to sales opportunities for the business to attack with shorter lead times.

- Traditional Process improvement advantages:

- Quick wins

- Lower cost

- Initial Capacity increase

- Get more with what you have (no significant capital investment)

- Possibly better with lead time improvements

- Automation advantages:

- Quality control improvements

- Repeatability metrics

- Maximize potential Capacity

- Compliance/regulatory requirements

- Digitization allows Data acquisition

- Rule of thumb: Reduce waste then Reduce processing times

If you have any questions that didn’t get answered in the panel or here please feel free to reach out.

Or if you are looking to start your Optimisation and Automation journey drop us a line: contact@omnatec.com or https://omnatec.com/contact