History of Industrial Robotic Arms

Industrial robotic arms started on automakers’ assembly lines in the mid-20th century. Their journey began in 1961, when the first industrial robot, Unimate, was installed in a General Motors assembly line. Unimate was tasked with dangerous tasks such as welding and transporting heavy dies to reduce the risk of poisoning or maiming human workers.

Throughout the following decades, robotic arms were used in more and more applications, especially in the high-turnover areas of automobile assembly. Helped along by the invention of the “Standford Arm”, commercialised around 1970, it was the first robot with six degrees of freedom. Subsequently, microcontrollers, improved joint kinematics, and upgraded sensor technology were included, and robots began to look like what we see today.

By the 2000s, robotic arms were present in the automotive, electronics, and aerospace industries, performing tasks from assembling and painting to inspection and packaging. However, traditional robots were large, costly, and required extensive safety barriers to protect human workers. This limited their application to large-scale factories with substantial investment in infrastructure. It was at this point that the idea of collaborative robots, or cobots, began to take shape.

What is a Cobot?

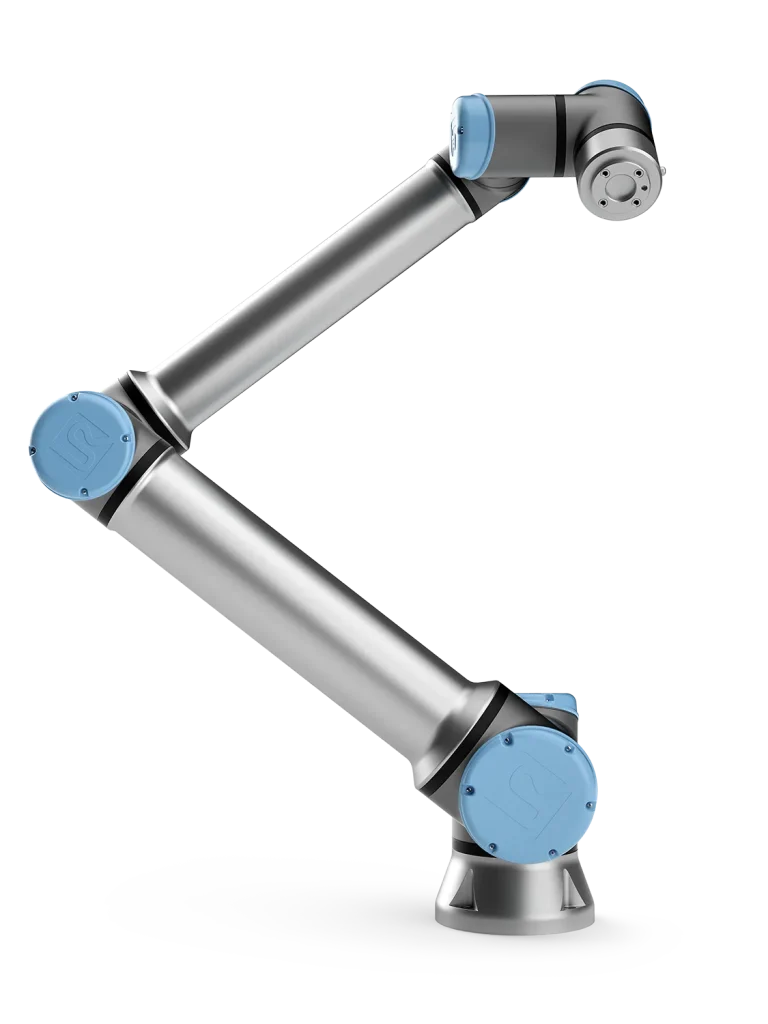

A cobot, or collaborative robot, is a type of robotic system designed to work alongside human workers in shared spaces. Unlike traditional industrial robots, which are typically isolated in safety cages due to their power and speed, cobots are engineered with safety in mind. They feature force sensors, machine learning algorithms and adapted hazard assessments that allow them to interact safely with human operators.

Cobots are typically smaller, more flexible, and easier to program than traditional robots. They are designed to assist with repetitive or physically demanding tasks without replacing human workers entirely, making them ideal for a wide range of industries. The collaborative nature of cobots allows for a more human-centred approach to automation, where robots augment human capabilities rather than replace the workforce.

Why Use a Cobot?

Cobots are becoming increasingly popular across industries for several reasons:

Safety: When properly configured, cobots can be an ideal solution for factories with small install areas and tight footprint requirements. Cobots are equipped with safety features such as force-limiting technology that can help reduce injuries in case of accidental contact. A comprehensive hazard analysis is still required, but it is possible to deploy them without physical barriers, reducing floor space requirements.

Flexibility: Unlike traditional industrial robots, which often require specialised programming knowledge, cobots are designed to be user-friendly. Cobots can be quickly reprogrammed and redeployed to handle different tasks, making them highly adaptable to changing production needs. This versatility is especially beneficial for small and medium-sized businesses looking to integrate automation without the rigidity of industrial robots or traditional automation solutions.

Enhanced Productivity: Cobots help reduce downtime and increase efficiency by taking on repetitive, mundane tasks. Cobots are often a workforce multiplier, allowing a single worker to complete work in parallel to the cobot and double or triple the output.

In some applications cobots work less in a “collaborative” sense but instead take on dangerous or monotonous tasks in their entirety, this allows human workers to focus on more complex, creative, or supervisory roles.

Top Cobot Applications

Cobots are now widely used in various industries. Some of the top applications include:

Assembly: Cobots excel in small-part assembly, helping to speed up production lines while maintaining precision. In industries like electronics, automotive, and medical devices, they handle tasks such as inserting components, fastening, and soldering. They work well in semi-automated situations, with the cobot being a workforce multiplier for the operator.

Machine Tending: Cobots are increasingly used in machine tending tasks, such as loading and unloading materials into CNC machines, lathes, and injection moulding machines. They work seamlessly with machines to keep production lines running smoothly and allow “lights out” operations to take advantage of untapped production capacity.

Quality Inspection: With integrated sensors and vision systems, cobots are ideal for quality inspection applications. They can inspect products for defects, measure components, and ensure that finished goods meet quality standards without human error. This is often a key step of both assembly and machine tending applications. When used in conjunction with other tasks, a final quality review step can help identify issues with raw materials or the process.

Welding: One of the earliest applications for industrial robots was welding, and cobots have found their place in welding as well. Cobots are precise and consistent, but they are also flexible enough to handle changing weld patterns for low—to medium-volume products. They can also take over simple welding tasks, allowing human welders to focus on more complex welds and fit-ups.

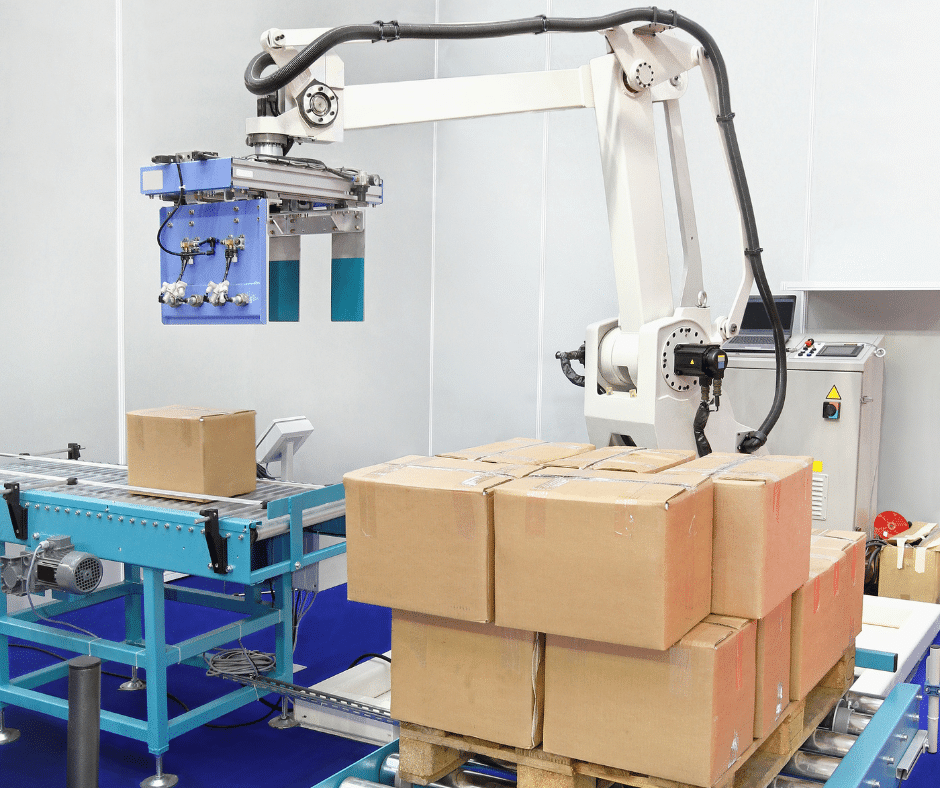

Packaging and Palletising: Cobots are highly efficient in packaging and palletising tasks, where they can handle a variety of items with care and precision. This is especially useful in mid-sized food, beverage, and logistics industries where quick, repetitive handling is required, but there is also high product variation to account for, so a full industrial solution either can’t fit or isn’t practical.

ROI with a Cobot

If you are an SME manufacturer, it can be hard to find the right place to automate that will give you a quick return on investment. Often, manufacturers of this size have a high mix and low volume ratio. This makes it hard to find a place in your factory where you do enough of one thing to automate it.

Cobots are a great solution as they can run a different program each day or week, they are smaller and can be mounted on mobile units to redeploy them in different areas of the factory, and the force feedback sensors allow less caging with a reduced footprint. They also offer a scalable solution where a project can be started with a single cobot and then added as experience and feedback is gained.

One place to look at your factory for a cobot opportunity is the end-of-line packing and palletising operation. If your factory uses manual labour to load pallets, then a Cobot palletiser is one of the fastest ways to achieve a return on investment. (It could be as little as 12 months!) Cobot palletisers can handle a variety of boxes, and some solutions are even mobile to allow moving from one conveyor to another, depending on factory demand.

To begin your journey with a Cobot: Start with OmnaTec

Industrial robots started with large, high-volume automobile manufacturers but have made their way into factories across industries and sectors. Smaller manufacturing companies can use cobots to reshape their operation by providing a safe, flexible, and cost-effective solution for a wide variety of applications. Their ability to collaborate with humans in shared workspaces offers unique opportunities for businesses to enhance productivity while maintaining a human touch. The potential ROI, coupled with the agility and versatility cobots offer, makes them an attractive choice for companies looking to stay competitive in their industry.

Omnatec is the ideal partner to get you up and running with a cobot. Peter Shafe is one of the directors of OmnaTec, and his primary goal is customer satisfaction. If you are looking for a pick-and-place solution or are looking to streamline your current palletising operation, Peter can help you scope your project, design the solution and install it onsite. His experience with cobots, robotic arms and traditional automation will ensure your project is set up to succeed and delivered as promised. Drop him a message today or set up a meeting to discuss your problem.