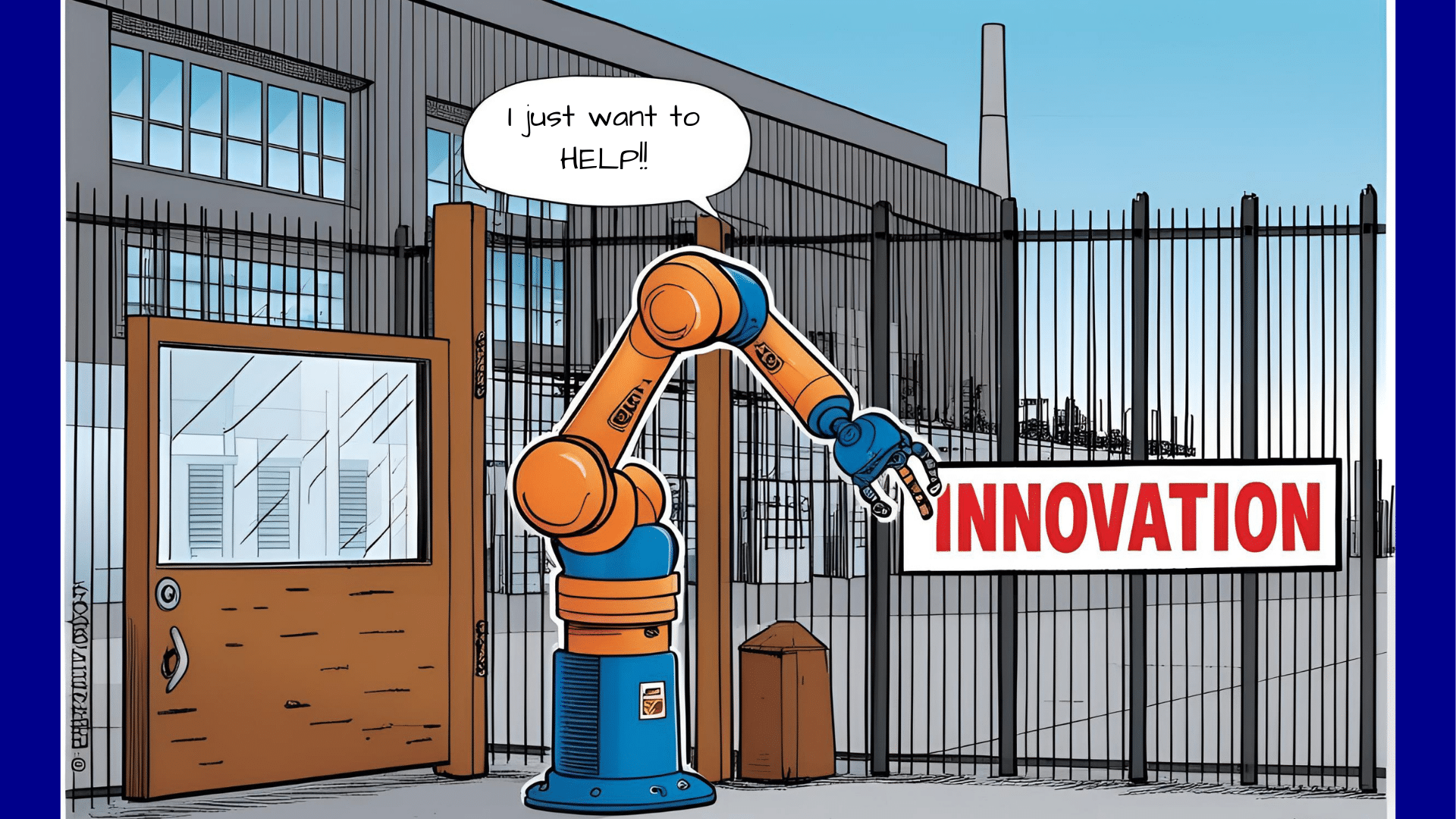

Is “innovation” becoming a barrier rather than a bridge to automation for UK SME Manufacturers?

While headlines and funding streams celebrate cutting-edge breakthroughs, many small manufacturers simply need reliable, tried-and-tested automation equipment, robotic arms and/or conveyors tailored to their day-to-day tasks.

The Innovation Buzz vs. SME Reality

Government grants and industry awards celebrate “novel” solutions such as AI-driven vision systems, machine-learning predictive maintenance, even bespoke hardware designs. Yet most UK SMEs face three core constraints when considering automation:

- Limited capital (typical automation budgets under £75,000)

- Highly specific workflows (custom batch sizes, unique packaging)

- Tight timelines (ROI expected within 18–24 months)

When “innovation” implies sky-high R&D costs or unproven prototypes, it can intimidate owners. They worry: “If it’s truly new, can I afford it? And what if it doesn’t fit my line?”

Does Innovation Equal Expense?

It’s easy to link “innovative” with “expensive.” Big-budget case studies with multi-million-pound smart factories dominate media attention. But for an SME making £2 million turnover with a 15% margin, a £100,000 automation project represents over 30% of their annual profit. That’s a heavy commitment.

Reality check: most grant-backed programs cap awards at £100–£150k, matching the budgets of the typical Tier 2 or Tier 3 manufacturer. When applications demand projects must be “innovative,” companies fear they’ll miss out unless they reinvent the wheel.

Off-the-Shelf or Off-the-Table?

When you hear “off-the-shelf”, many manufacturers imagine locking themselves into rigid, one-size-fits-all systems that will require compromising their existing processes. In truth, almost every automation deployment is a bespoke combination of standard modules. How we use the motors, PLCs, linear actuators, end-of-arm tools to meet a factory’s layout and cycle times is the important bit.

Key misconceptions:

- Standard = Inflexible The equipment components may be standard, but it can be combined and integrated in countless ways.

- Custom = Cutting-edge The solution will be custom to you, and the productivity effects may feel cutting edge, but at its core will be tried-and-tested equipment.

- Innovation = New and Shiny Innovation doesn’t have to come from some big new piece of kit. It may be a simple semi-automated jig or a reorganisation of your line to eliminate waste

True Innovation Is in the Details

For an SME still palletising by hand, the very act of integrating a cobot palletiser is innovative. Every workflow quirk, including small batches, variations in box size, seasonal product runs, all demand a creative solution from the integrator. That’s where genuine novelty lives: not in flashy AI dashboards, but in the flexible sequences, quick-change fixturing, and lean layouts tailored to your shop floor.

The Bottom Line for UK SMEs

- Innovation is mindset, not price tag. A £20 k cobot with smart end-of-arm tooling can transform throughput—no blockbuster R&D required.

- ROI wins over novelty. Focus on projects that pay back in under two years.

- Bespoke standardisation is your sweet spot. You get reliable hardware plus custom control logic—maximum uptime, minimal risk.

By reframing “innovation” as the clever application of existing technology, all assembled around your needs, SMEs can avoid the hype and start increasing productivity today. After all, sometimes the most groundbreaking step forward is simply making things work better for you.