FANUC is a world-recognised brand making robots, CNCs and controllers, but they’re best known for their industrial robots. In fact, they make the world’s “strongest” robot with theirM-2000iA Series robot which has a payload of 2300kg! (https://www.fanuc.eu/eu-en/product/robot/m-2000ia2300)

However, in 2022 Fanuc also brought out a cobot line called the CRX series. These cobots include some cool features not available on the industrial robots, one of which is the Touch Skip functionality. This built-in capability lets the robot “feel” its way through a task without needing extra sensors. (https://www.fanucamerica.com/news-resources/fanuc-america-press-releases/2022/09/27/fanuc-demonstrates-new-robotic-solutions-at-assembly-2022)

What is Touch Skip?

In simple terms, Touch Skip enables the robot to detect when it comes into contact with a surface or object. When a preset force threshold is exceeded, the robot stops, records the contact point, and then adjusts its motion accordingly. This built-in touch sensitivity means you don’t have to rig up external sensors to get similar functionality.

It’s very easy to set up too. You just have to program the starting point, the final point, the speed, and the force threshold. Then after the function is done, you get outputs of whether it reached the final point or stopped early as well as the position it was in when it stopped.

Why Touch Skip is so Useful

For tasks which have variations in the size of the parts or in the size of the stacks they are either placed or picked from, a way of dynamically finding the position is very useful. Traditional industrial robots usually depend on external force sensors for similar tasks, but also tend to have less variability in their system so need this functionality less. Cobots, by design, tend work with more human interaction and have to deal with more variation. It is better to teach a cobot to deal with the possible variation than it is to trust a human to never make a mistake. Because the CRX uses its integrated sensors, users get several benefits:

- Faster programming and Commissioning: With the sensor built into the system, setting up the robot becomes less complicated.

- Cost Savings: Though the decision between robot and cobot should not come down to cost, but application requirements, fewer external components might mean lower cost and maintenance.

- Improved Reliability: Fewer components mean there are fewer points of failure, making your operation more robust overall.

Real-World Applications

Touch Skip shines in scenarios where precise physical interaction is essential, but the variation is high, and adaptability is required. Here are a few examples:

- Surface Following: Whether it’s polishing or deburring, the robot can maintain consistent contact with uneven or curved surfaces.

- Part Detection: It can detect the presence and position of parts during pick up, assembly or placing operation meaning if raw components like billets are refilled at intervals the cobot can continue to work without a stopping and restarting.

- Adaptive Insertion: When inserting components with tight tolerances, the robot adjusts its movements based on real-time feedback, leading to smoother, more accurate operations.

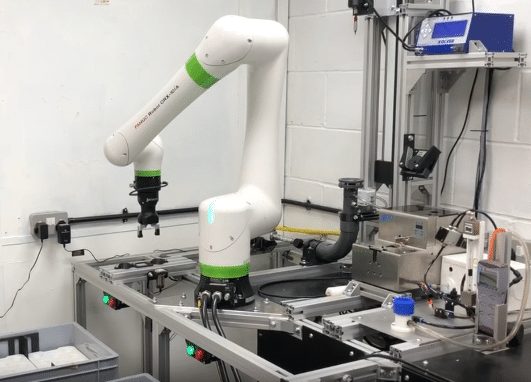

OmnaTec used the Touch Skip functionality in a number of places in a recent cobot solution.

- Tray heights – The tray stacks could have between 1 and 5 trays in each stack

- Part variants – This application had several component variants and the Touch Skip function could be used to deal with variation in heights.

- Part location (on thread) – On one step the a part was threaded onto a jig. Depending on when the thread was picked up there is some variation on the top of the part. This variation was overcome with the Touch Skip function.

In our video, you can see the robot looking for the top of each tray. It stores that location, then determines which stack is the tallest and then goes and picks the tray from the tallest stack. The pick can happen faster as it knows where it “found” the top tray in the previous search step.

Any Negatives?

The only difficulty we found was not being able to set an Offset or Incremental move for the final point. For example, we would have found it useful to set the Start Point and then set an incremental movement of 100mm in -Z direction. We were able to make a workaround with an extra bit of code, but that was really our only complaint.

Final Thoughts

FANUC’s Touch Skip functionality in the CRX cobot series gives users an easy to use function that can enhance adaptability while reducing system complexity and costs. It’s a good example of how cobots can make “collaboration” easier and help manufacturers make the jump into robotic automation.

If you are keen to learn more about how OmnaTec can help you take advantage of the Touch Skip function or other cobot functions to improve your manufacturing processes, then please take a look at our industrial automation solutions and get in touch.