Low Waste Processes

In Part 1 of our Lean blog posts, we learned about the “Toyota Way” or the Toyota Production System (TPS) (https://www.toyota-europe.com/world-of-toyota/this-is-toyota/toyota-production-system) and how they were the first to think about waste in its different forms and identify time as the most precious of commodities. We looked at the Iron Triangle to consider cost, quality, and time. (https://www.prince2.com/uk/blog/project-triangle-constraints)

The traditional production and financial mindset is to focus on cost. This thought process is that low cost will equate to higher margins and more profit. The Lean mindset focuses initially on time (i.e. make it efficient) and secondly on quality or production stability (i.e. keep on making it) with cost being a pleasant result. With this post, we will now focus on the quality of the process.

Quality of the Process

We all recognize the quality of a product is important for customer satisfaction and good brand perception. However good product quality comes from good process quality or process stability. There are many metrics and methodologies for looking at this, including Availability Percentage, uptime/downtime ratios, and Fully Productive Time ratio (TEEP) but the lean methodology is interested in Overall Process Efficiency. (https://gomingo.io/oee-vs-ope-teep-which-should-manufacturers-calculate/) This uses the Equipment or Process Efficiency of the individual steps in the process and calculates an overall efficiency.

Start with each step

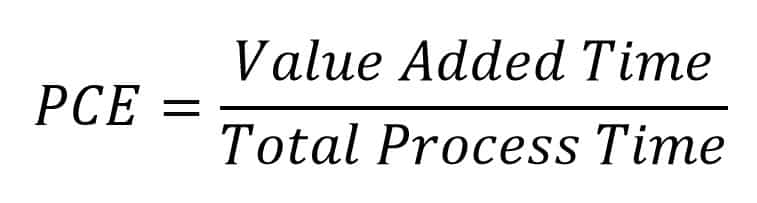

The Process Cycle Efficiency (PCE) is calculated for each step. It tells us what percent of the total processing time for that step is consumed by waste. As you remove waste your PCE goes up. Zero waste equals 100% efficiency!!

Put it all together

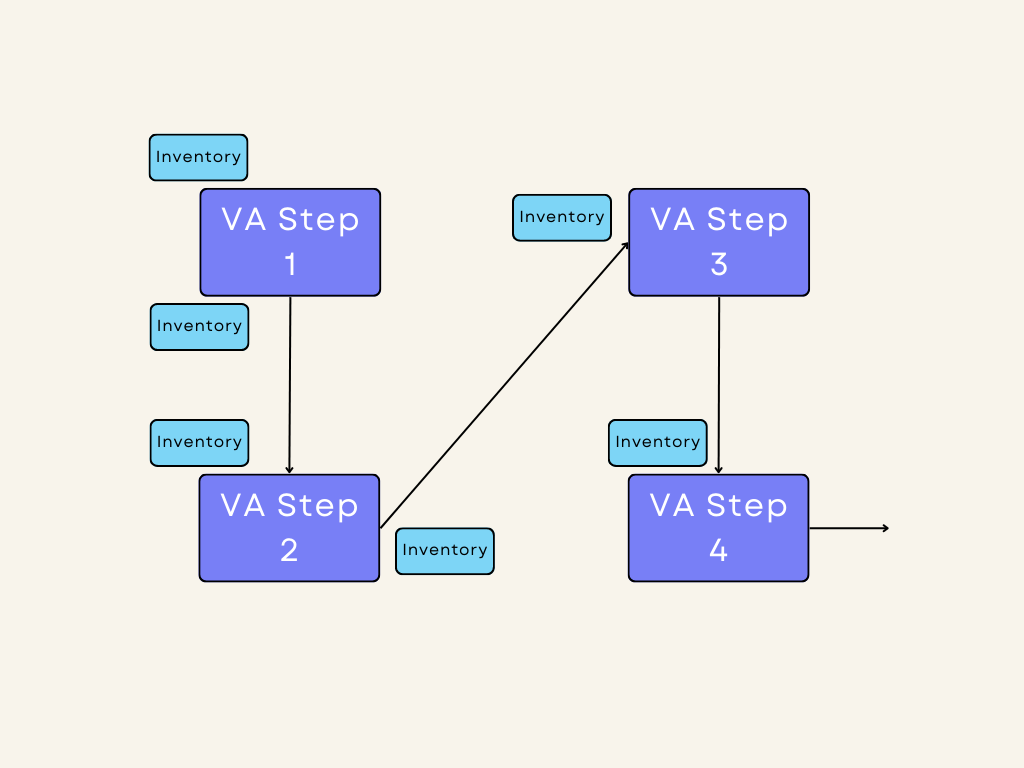

Take a stereotypical process in which each Value-Added step in the process takes one minute and runs with 80% efficiency. In this unoptimised example, your PCE will be very low as there will be waste in terms of transport, inventory, overproduction, waiting, motion, etc.

On the positive side, if there is a problem with one of the substeps such as: equipment failure or a process defect being identified, the whole process will hardly be affected.

The inventory buffers surrounding the downstream steps will allow those subsequent steps to be completed. Due to this fact, the overall efficiency is 80%! (or whichever step has the lowest efficiency.)

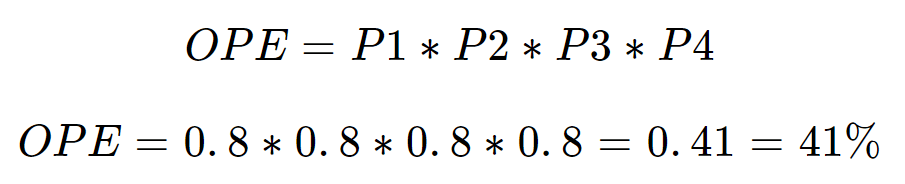

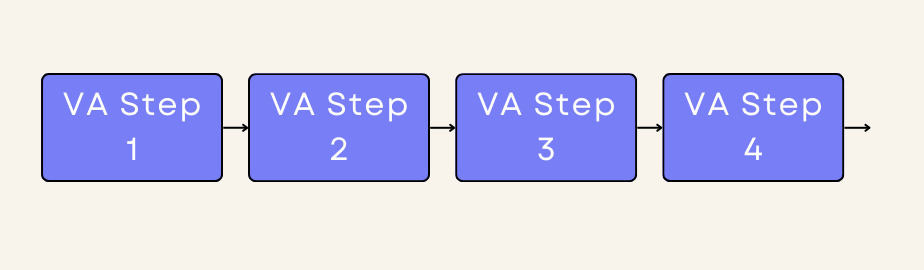

However, if we eliminate these wastes, improve the PCE, and have a process with just the value-added steps, the overall efficiency becomes the product of the efficiency of each of the sub-steps or in this example:

This means: in a low-waste process, the quality or stability of the individual process needs to be higher to achieve the same OPE. In fact, to get the same overall efficiency as the wasteful process we would need to have the individual efficiencies be 94.6%.

How to ensure a high-quality process?

In order to achieve the higher level of quality required, the second tenet of a Lean mindset must be put to work. This tenet is to improve the reliability and quality of the process. There are many Lean tools to help do this.

- 5S, the 5S’s are Sort, Set in Order, Shine, Standardize, and Sustain, is the most famous Lean tool. This is usually used as a waste reduction tool, but can also help improve the quality of a process as the right tool for the job is always available, marked, and within reach. To paraphrase Abraham Maslow, “If the closest tool is a hammer, everything looks like a nail.”

- Total Preventative Maintenance (TPM) helps plan the maintenance of the machines which reduces unplanned downtime and increases the process quality

- Poka Yoke tooling helps eliminate errors in processes with a human element. This reduces rework and keeps the overall efficiency high.

- Continuous Improvement and non-conformity identification. When non-conformities are identified, they are an opportunity to improve the quality of the overall process. It is important to ensure a Root cause is identified and addressed. A powerful Lean tool is PDCA or Plan, Do, Check, Act. This cyclical process helps encourage a structured “Get it done” mentality with a close eye on metrics and feedback.

If, in the end, the individual steps cannot maintain the required efficiency, then some “waste” can be added back into the process in the form of buffer stock or other quality controls.

Next Steps

The end result of reducing waste and optimizing quality is a highly efficient process that frees up capacity for further production to be turned into orders and revenue.

If you need help removing waste or improving the quality of your process, drop us a line!