Automatic assembly machines are used by many industries to manufacture their products. They can save a lot of time and money for manufacturers, but the process of designing, building, and installing one can be complex. There are many different types of automatic assembly lines with varying levels of complexity and cost. In this article we’ll look at who designs these systems and what you need to know in order to get started with your own custom system!

Who Designs and Builds equipment for Manufacturing – Industrial Designers!

An industrial designer can be a bit of a misnomer as they generally focus on designing products with a specific interest in the human interaction. This could be consumer products or industrial machinery. In the industrial market, the products that an industrial designer might create can range from hardware such as machinery, to software for a user interface. Industrial designers have a unique way of looking at things and find solutions to make them intuitively easier for the users by focusing on the human factors issues like ease of use and efficiency.

What skills do Industrial Designers need to create machine making machines?

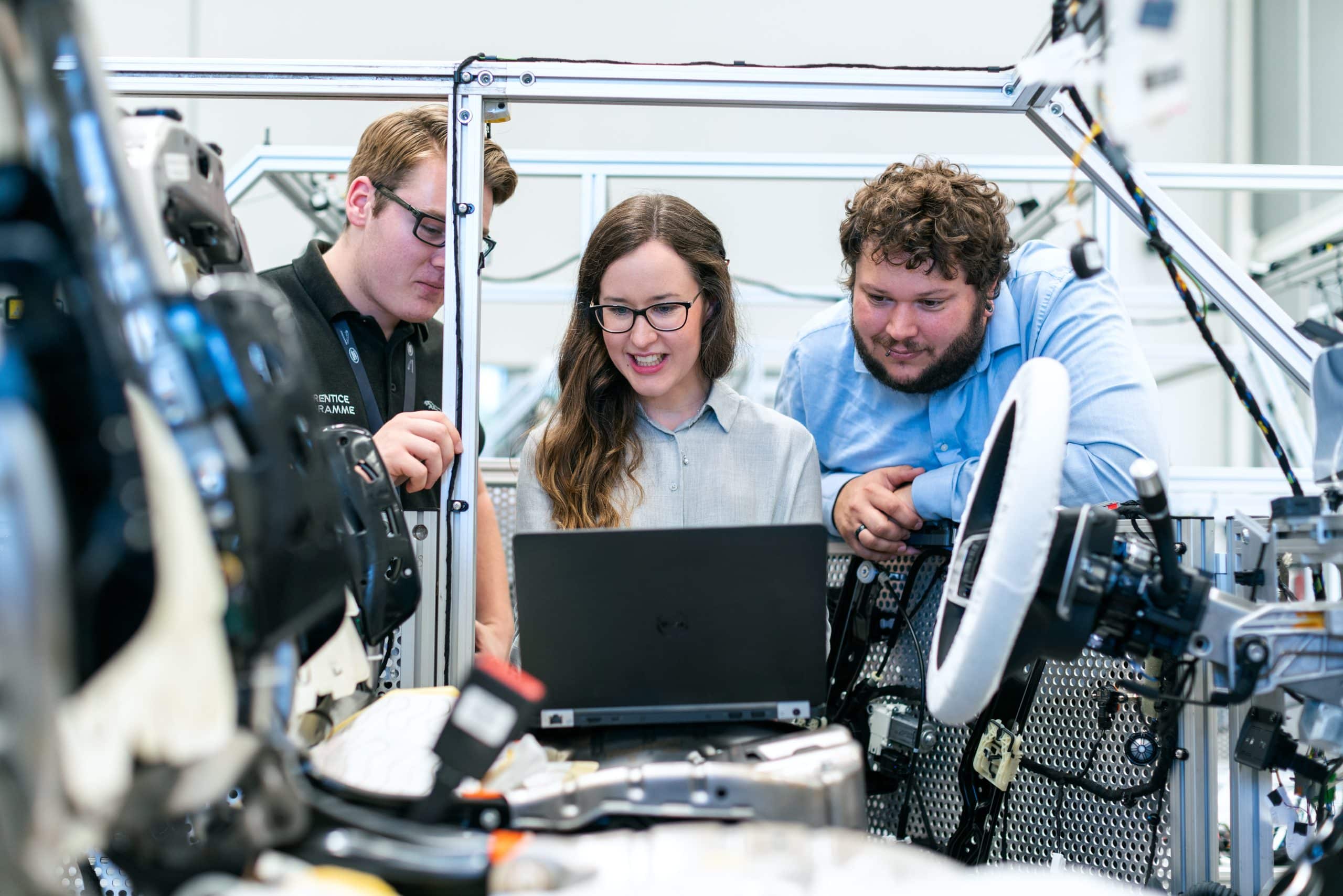

Converting a manual or semi manual process into an automatic one can be a bit of an art, and the industrial designers who create these machines are experts. These individuals and companies need to gain a deep understanding of the industry their machine will be used in. Most often this key information is gained though onsite interviews with the operators, meetings with the leadership team and a review of the technical specification for the process/product. These are the individuals you want to talk with if you want a custom machine making machine.

The skills required to be an industrial designer include:

- A background in mechanical/electrical engineering or similar fields

- A thorough understanding of how controls systems work

- Experience designing automated machines for the industrial environment

How do I get an automatic machine to make my product?

Is your product/process complex?

If you have a product that is unique and complex, then we will need to design and build a more bespoke machine that allow us to assemble it. This may take some time and possibly be rather costly. You may want to think about breaking your product assembly processes into some sub-assemblies and looking at automating one or two. Another possibility is that you look at a semi-automated processes which still requires some human interaction, as it can be more cost effective to deploy. Speaking to someone to explore your options is always a great idea to see what it possible.

Or is it a slightly more straightforward journey?

Many customers want to reduce costs, and they may use existing standard machines from a catalogue to construct all or part of their automatic assembly line. A good example of this might be an off the shelf box folding machine. In many cases, choosing an off the shelf option helps save money.

There are several reasons why using existing standard machines can be advantageous:

- Customers save time by not having to design and build new hardware for every step in the process.

- The customer gets the same quality as a custom system at lower cost because it’s easier for firms like ours (that specialize in automated machinery) to know exactly what parts work best together based on years of experience with similar products that have been built before yours was ordered!

For most products there is no need to build an entirely custom system, so the cost is likely cheaper than you think.

Usually there is no need to build an entirely custom system, so the cost is likely cheaper than you think. If you want something more specific, then it will usually come at a higher price tag. Using the expertise of an industrial designer means you get the optimum blend of cost and functionality by using off the shelf components alongside any required customisation, so the result is perfect for your needs.

If you’re considering having a machine made specifically for your own business needs or even as part of an existing production line, it’s important to consider the cost involved in doing so before making any final decisions about what kind of equipment (if any) would work best in your situation; however there are many other factors that go into deciding whether building one might make sense over buying pre-made pieces instead (including space constraints and maintenance costs).

In either case you should think about creating a technical specification

The customer should provide a basic scope document with details about their product, technical specifications, and other relevant information. It may contain a list of “must haves” and “nice to have”, regulatory requirements, KPI’s, space constraints etc. If you have any questions about what your specification needs or how a machine might fit into the process of making machines, feel free to ask!

There is no one-size-fits-all for industrial design

If you have any questions about the process, please do not hesitate to contact us so we can help you navigate through it. We will work with you every step of the way and make sure that your project is a success!