Select the Right Linear Motion Component

The electric motor has been a critical part of manufacturing since the Second Industrial Revolution. Now in the 21st century, the ability for electric motors to convert rotational motion into linear motion with efficiency and precision plays a crucial role in industrial automation. In this article, we will review the most popular mechanisms, and the advantages and disadvantages of each type—toothed belt drives, linear screws, and ball screws. Here we aim to provide a pragmatic understanding of the influences on these components’ selection. Speed, simplicity, precision, cost-effectiveness, efficiency and accuracy, each have benefits to keep in mind when trying to select the right Linear Motion component.

What is linear motion?

Linear motion is the controlled movement of an object in a straight line. It involves the translation of rotary motion, typically generated by electric motors, into linear movement of a component. This type of motion can be combined with multiple axes of linear motion to create complex three-dimensional motion which is fundamental in various manufacturing and automation processes where precise positioning, accuracy, and controlled movement are essential.

Here we will cover three types of componentry

- Toothed belt drives

- Lead Screws

- Ball Screws

These linear motion mechanisms are integral to a wide range of manufacturing tasks across various industries including

- Conveyor systems

- Robotics

- 3D printing

- Automated inspection system

- Assembly processes

- Packing and palletizing

- Numerous others…

Read on to find out how to select the right component for your application.

Toothed Belt Drives: Efficiency in Motion

Toothed belt drives use a toothed belt, usually made of rubber or synthetic material, engaging with toothed pulleys attached to a motor and the driven component. As the motor rotates, the teeth of the belt engage with the teeth of the pulleys, transferring motion along the belt’s length. This mechanism ensures a smooth and efficient translation of rotational force into linear motion.

The advantages of a Toothed Belt Drives are clear in high-speed, high duty applications, making them particularly effective in scenarios where rapid and continuous motion is paramount. When compared to the other systems covered in this article, their cost-effectiveness is another advantage. Commonly utilized in applications requiring speed over longer distances, toothed belt drives find their niche in applications where efficiency and cost considerations are critical factors, but precision is secondary.

Tooth Belt Drive – SIMO (https://www.expo21xx.com/)

Lead Screws: Low-Cost Precision

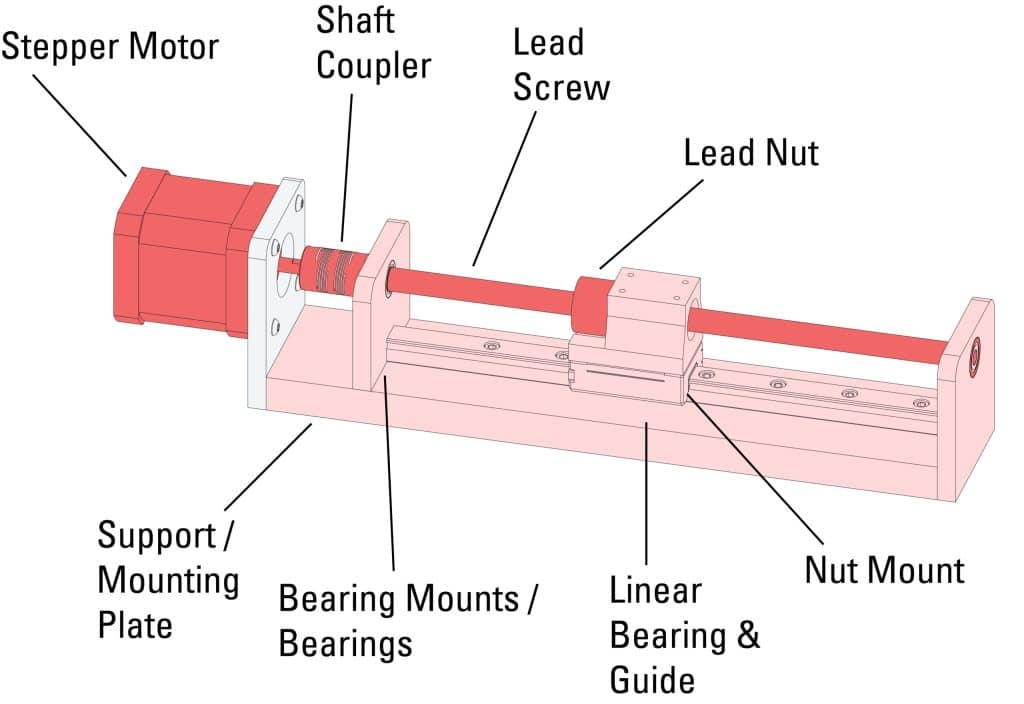

When thinking about linear motion, Lead screws are possibly the most basic mechanism. Dating back to the time of Greek mathematician and engineer Archimedes the screw thread is still an important component to consider. Lead screws feature a threaded shaft that engages with a nut, converting the rotary motion of the shaft into linear motion of the nut along its thread. This simple yet effective design allows lead screws to provide accurate positioning, making them a favourable choice for applications where improved accuracy is important.

Lead screws offer a cost-effective, easy-to-implement, easy-to-maintain solution across various industrial applications. They shine in applications where the loads are fairly light, the duty cycles are modest and positional accuracy is important. However, their limitations, in terms of speed and friction affecting the motor selection should be noted. Lead Screws can provide a great compromise of cost and accuracy if your application is appropriate.

Linear Screw Assembly (https://www.thomsonlinear.com)

Ball Screws: Enhanced Design for Maximum Efficiency

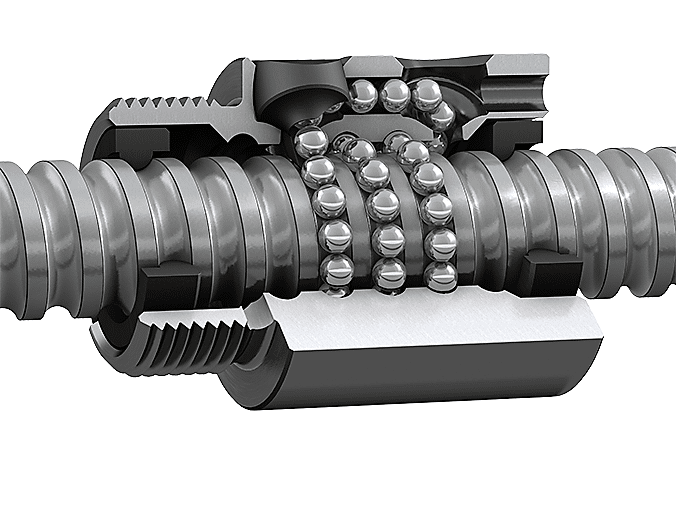

Ball screws are a sophisticated upgrade over Lead Screws, designed to minimise friction and optimise efficiency for precise linear movements. Similar to a lead screws the design of a ball screw involves a threaded shaft and a nut but, with the addition of ball bearings within the nut. As the shaft rotates, the ball bearings allow a smoother motion along the thread, significantly reducing friction and improving efficiency.

Ball screws offer many advantages over lead screws like increased load, speed and duty cycle; in addition, the higher efficiency allows smaller, cheaper motors to be used. They can be highly accurate if correctly specified and set. However, the extra complexity required to achieve this superior performance makes them more expensive to buy and repair. Also, the maintenance to ensure optimal performance can be more tedious and complex. When precision and speed are paramount the ball screw excels.

Linear Screw Assembly (https://www.thomsonlinear.com)

Linear Motion Summarised

Linear motion is a critical part of almost every industrial automation project. Hopefully, this article will help you understand the advantages of the most common mechanisms and guide you in selecting the right Linear Motion component.

At the end of the day each has their strong points and understanding your project specifications is crucial. Toothed Belt drives excel in applications where speed and simplicity are key. They also offer longer travels than either of the other options. Lead screws, on the other hand, provide a precise, low-cost alternative for light-duty applications. Finally, a Ball Screw’s enhanced design make them ideal for demanding industrial environments where speed, precision and load requirements justify the increased costs. The choice between these components depends on the specific requirements of the application, balancing advantages and disadvantages to achieve optimal linear motion outcomes.

If you need help selecting the right component, finding a supplier or with an automation project, big or small, drop us a line.

| Component Type | Advantages |

|---|---|

| Toothed Belt Drives |

|

| Lead Screws |

|

| Ball Screws |

|